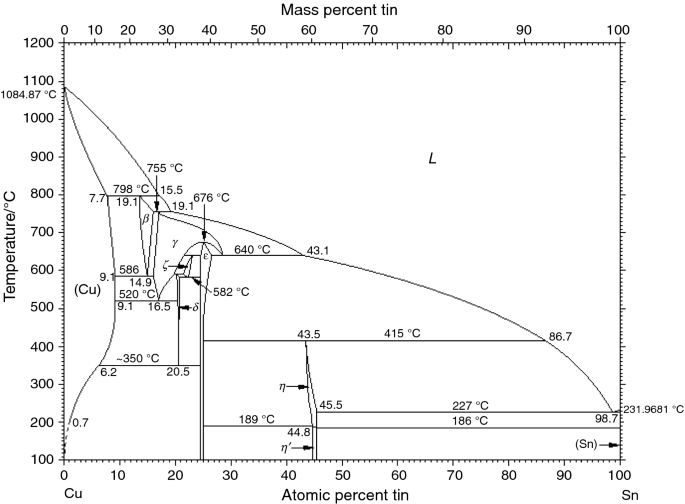

35 copper tin phase diagram

As a result, the metal's solubility in the organic phase is diminished, "stripping" the organic of the metal values. The copper enriched solution is used for electrowinning, where copper is electrodeposited in suitable cathode. Copper electrowinning is an important part of the copper hydrometallurgical process. Electrowinning is a sophisticated ...

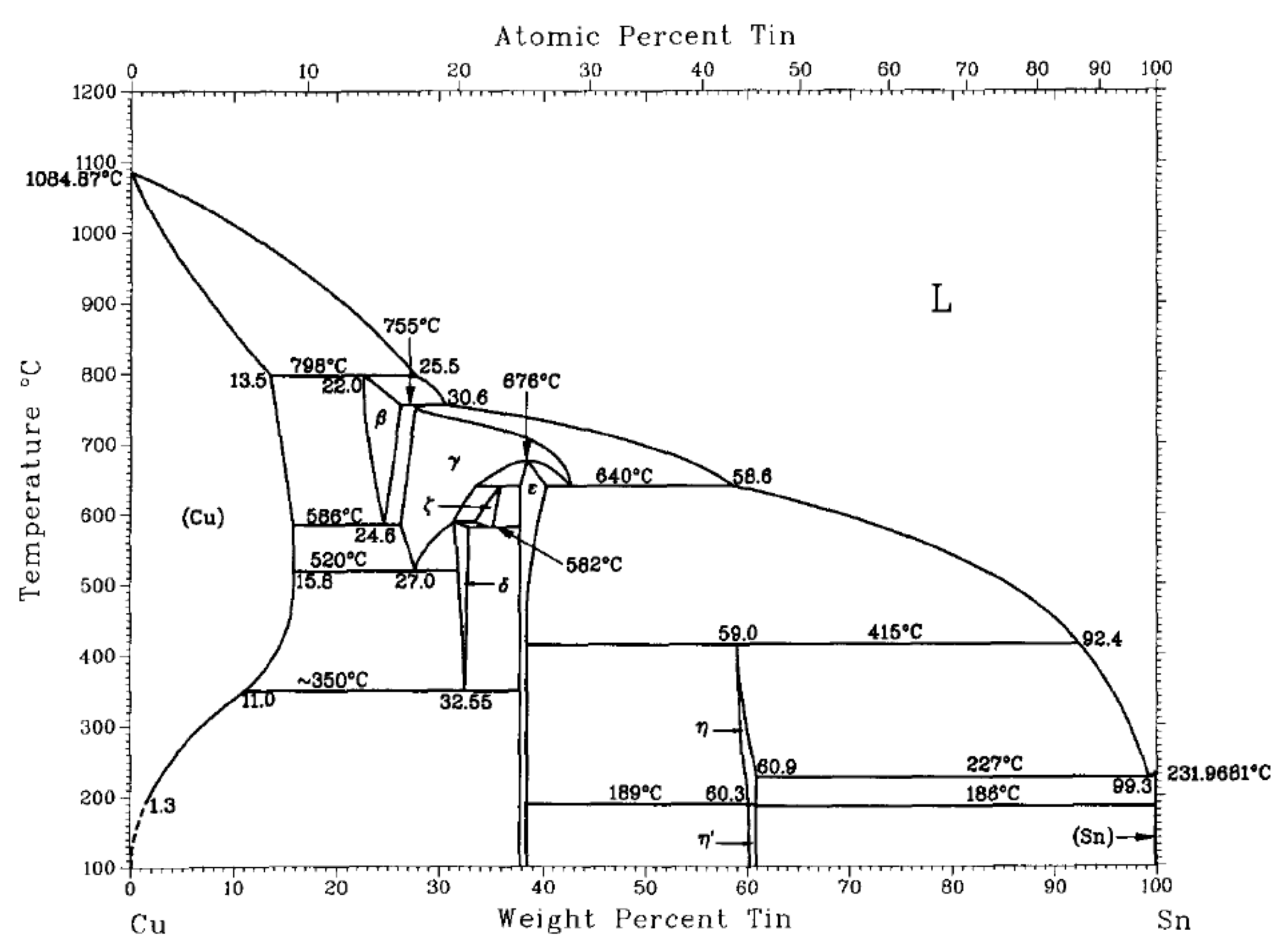

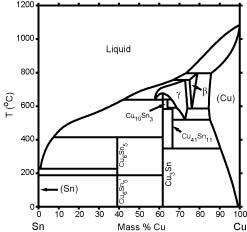

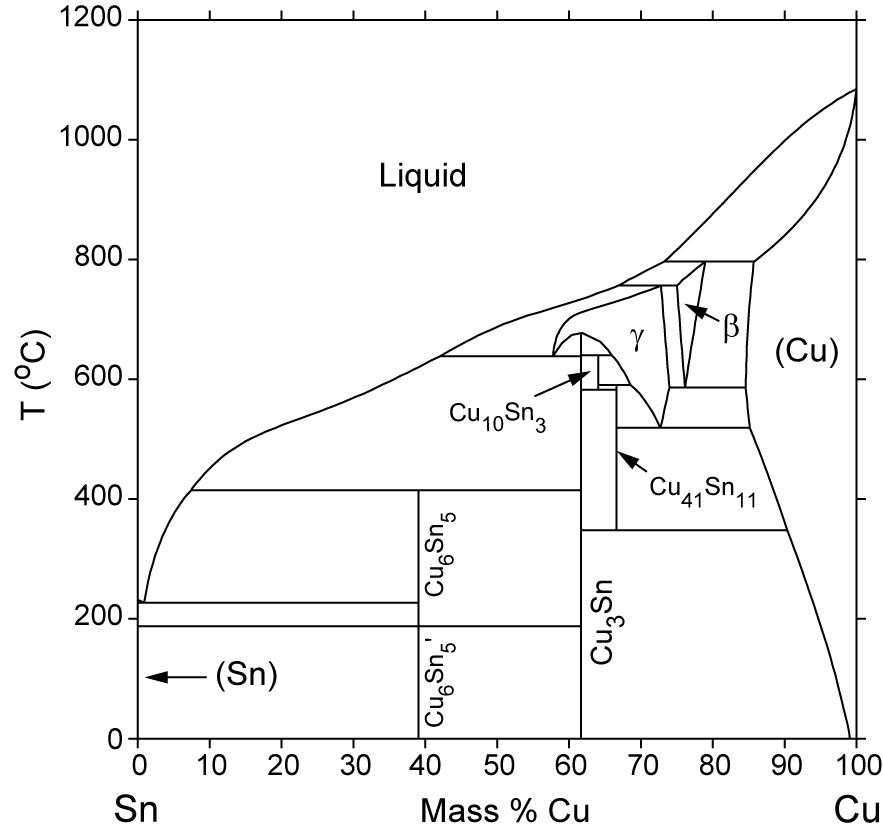

Download scientific diagram | The copper-tin phase diagram, compare [6] from publication: High Temperature Shear Strength of Cu-Sn Transient Liquid Phase ...

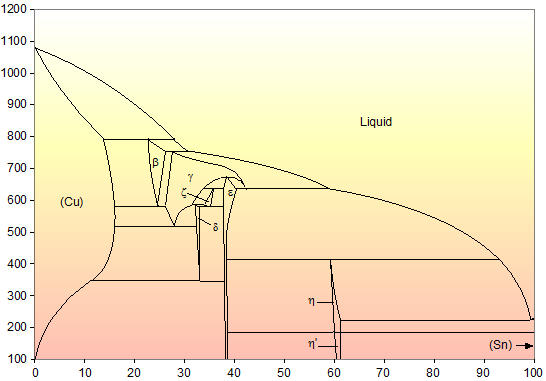

DoITPoMS Micrograph Library Phase Diagram for Cu-Sn. Micrograph Library Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagrams.

Copper tin phase diagram

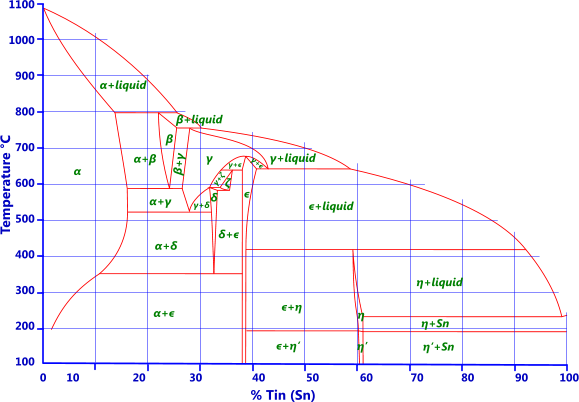

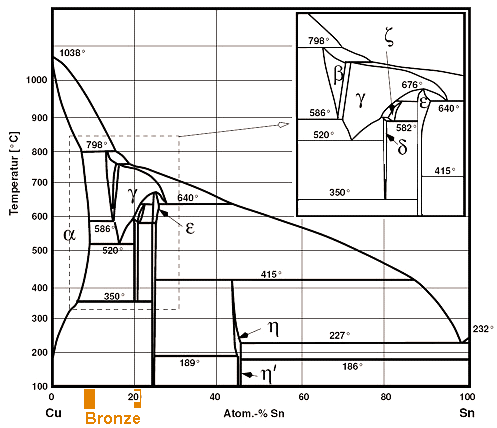

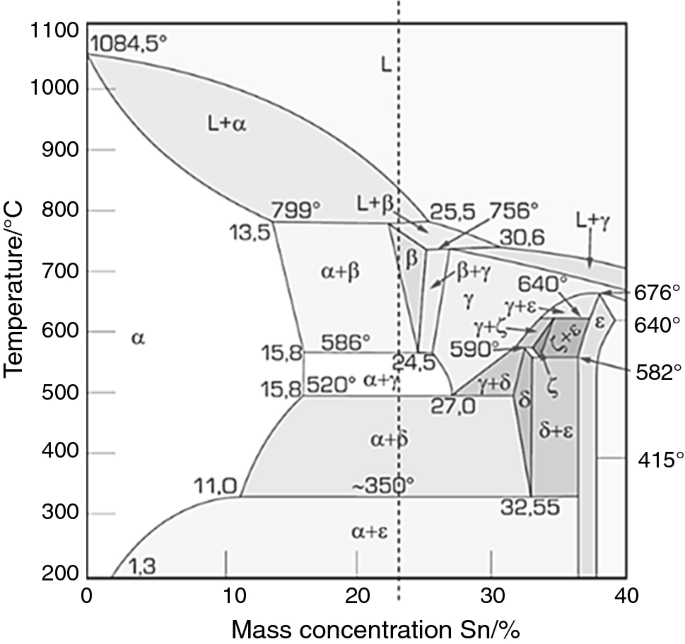

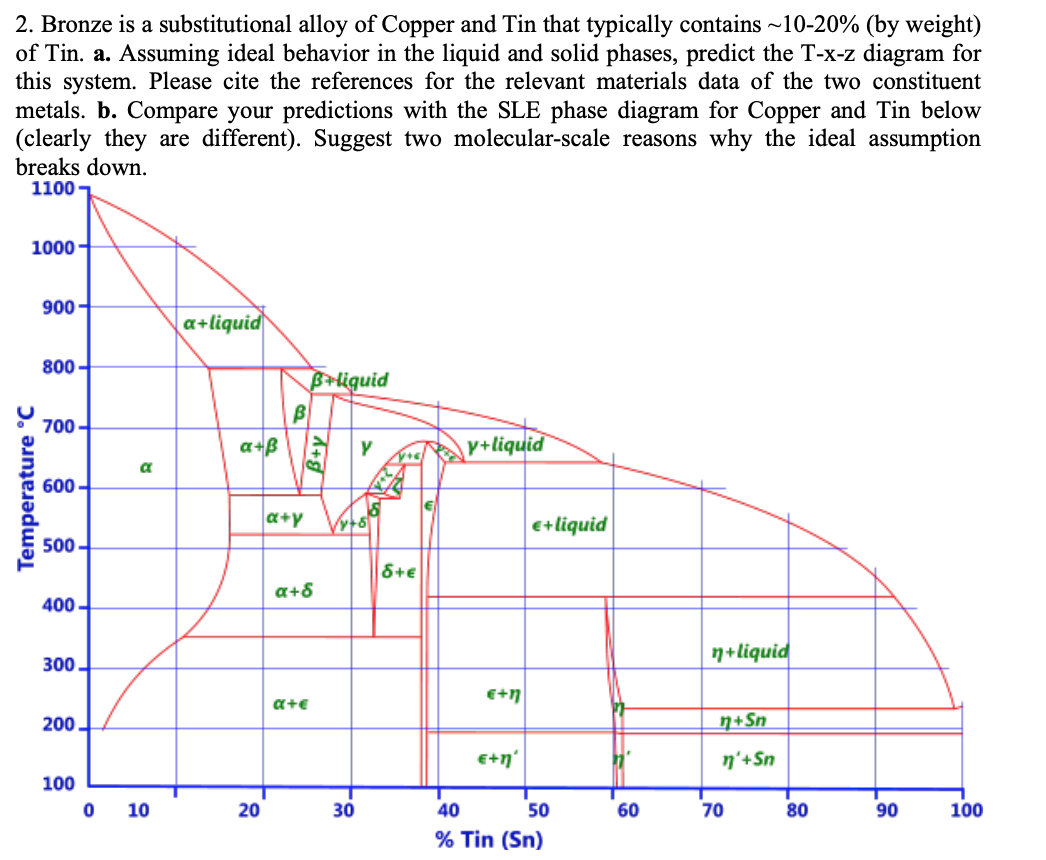

The system copper (Cu) - zinc (Zn). Let's start with copper (Cu) - tin (Sn). This system contains what we call "bronze". Here is the phase diagram: ...

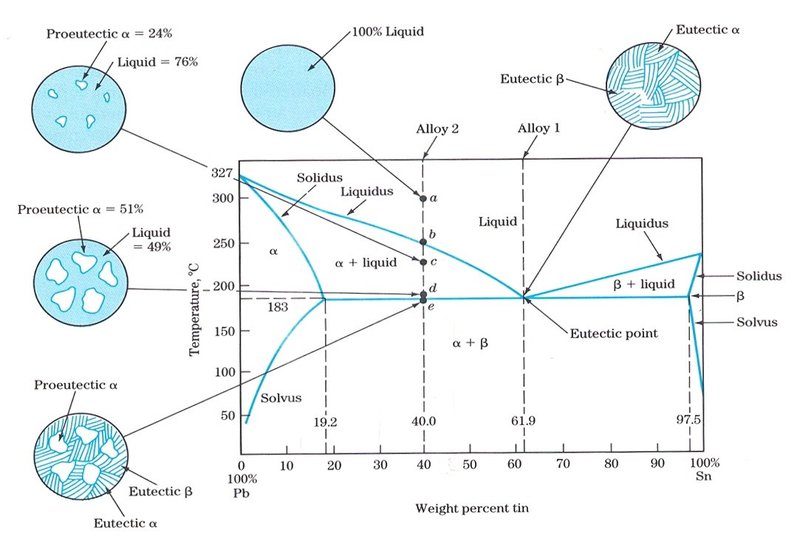

Copper – Silver phase diagram liquid α+ β Solidus Liquidus Temperature, Solvus ° C Composition, wt% Ag. MSE 2090: Introduction to Materials Science Chapter 9, Phase Diagrams 24 Binary Eutectic Systems (III) Lead – Tin phase diagram Invariant or eutectic point Eutectic isotherm Temperature, ° C Composition, wt% Sn Eutectic or invariant point- Liquid and two …

The Cu-Ni phase diagram (Figure 9.3a) is shown below; the point labeled “G” represents the 63.8 wt% Ni-36.2 wt% Cu composition at 1250°C. As may be noted, point G lies within the α phase field. Therefore, only the α phase is present; its composition is 63.8 wt% Ni-36.2 wt% Cu.

Copper tin phase diagram.

Several copper alloys have been developed in which the grain size is stabilized by the presence of a finely distributed second phase. Examples include copper-iron alloys such as C19200, C19400 and C19500, and aluminum-containing brasses and bronzes such as C61500, C63800, C68800 and C69000. These alloys will maintain an extremely fine grain ...

Fortunately, the equilibrium phase diagram for the faceting–roughening transitions for the Σ3 twin GBs in copper is known. In ... The lowest T eff around 800 K was observed for copper alloyed with indium and tin. The highest T eff of about 1300 K was observed for chromium and hafnium. Silver atoms are most close in their dimensions and properties to copper ones among …

Structure. Copper(I) iodide, like most binary (containing only two elements) metal halides, is an inorganic polymer.It has a rich phase diagram, meaning that it exists in several crystalline forms.It adopts a zinc blende structure below 390 °C (γ-CuI), a wurtzite structure between 390 and 440 °C (β-CuI), and a rock salt structure above 440 °C (α-CuI).

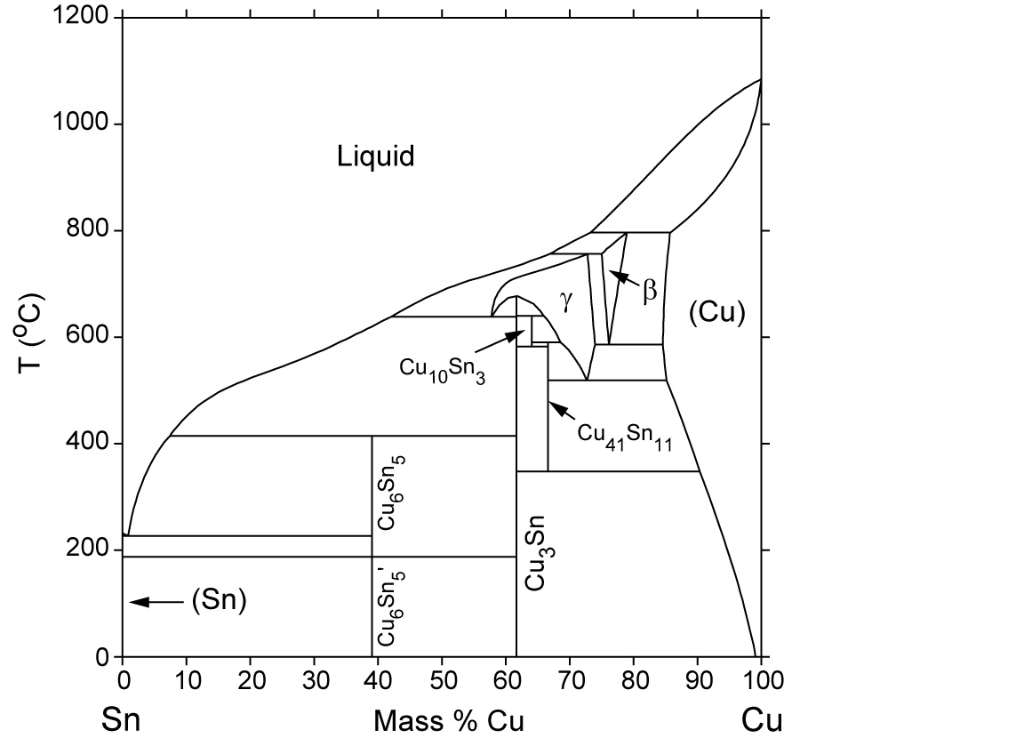

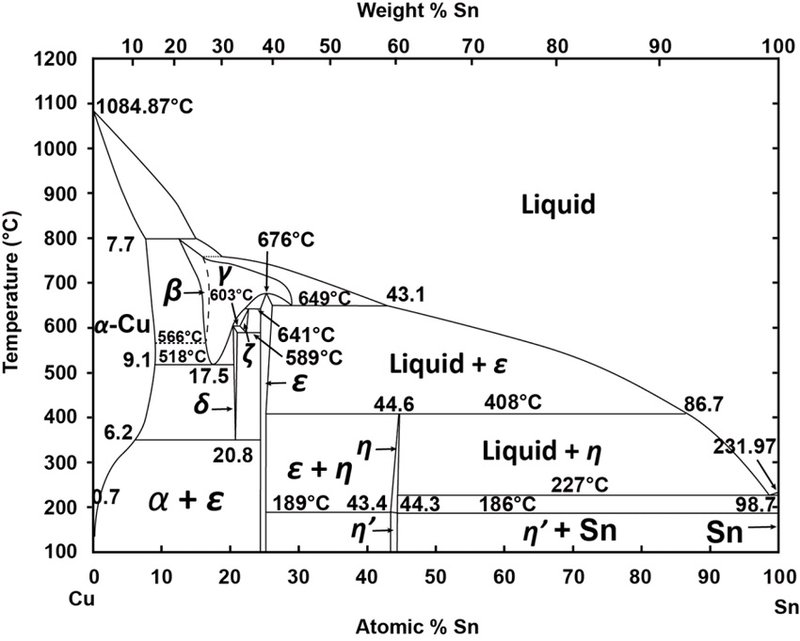

by S Fürtauer · 2013 · Cited by 193 — Phase diagram investigation of the Cu–Sn system was carried out on twenty ... because tin is the main component of most of such solder materials and Cu is ...

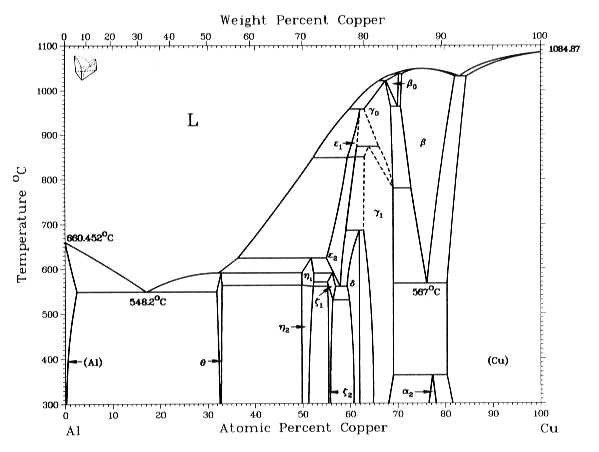

A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points , C, 74 wt% Zn) and P (598 C, 78.6 wt% Zn), respectively. Figure by MIT OCW. Note that each single-phase field is separated from other single-phase fields by a two-phase field. Lecture 19 – Binary phase diagrams 6 of 16 11/23/05 . 3.012 Fundamentals of …

The copper-tin equilibrium phase diagram (Figure 3) illustrates Cases (1) and (2). Figure 3. Copper-tin equilibrium phase diagram (Reference 2). Case (1) - Substitution. Figure 4. Microstructure of a single-phase (alpha) copper-tin alloy (88Cu-8Sn-4Zn). Structure shows slip lines. Note also traces of the delta phase (darker islands) (Reference 2). Referring to Figure 3, …

by S Fürtauer · 2013 · Cited by 201 — The binary system CueSn is the key system for lead-free soldering, because tin is the main component of most of such solder materials and Cu is ...

Copper-Tin Alloys — Copper tin phase diagram showing a peritectic point. The peritectic reaction (see diagram above) is an important example of a ...

by N Saunders · 1990 · Cited by 285 — Liquid Binary Alloys of Arsenic with Tin and Thallium," Z. ... 1 Assessed Cu-Sn Phase Diagram. 0. I0. 20. 30. 40. Weight. Percent. Tin.10 pages

Selected copper alloy diagrams illustrating ... The copper-tin binary equilibrium diagram is complex containing a peritectic reaction and a.36 pages

Phase at STP: solid: Melting point ... Bronze usually refers to copper-tin alloys, but can refer to any alloy of copper such as aluminium bronze. Copper is one of the most important constituents of silver and karat gold solders used in the jewelry industry, modifying the color, hardness and melting point of the resulting alloys. Some lead-free solders consist of tin alloyed with a small ...

For soldering, tin-silver and tin-copper solders – e.g. S-Sn97Ag3 and S-Sn97Cu3 to EN 29453 - should be considered – using types 3.2.2, 3.1.1, 3.2.1, 3.1.1, 3.1.2, 2.1.2 and 2.2.25 fluxes to EN 29454, Part 1. Flux residues should be removed after soldering. The above solders have better mechanical properties and higher heat and corrosion resistance than the lead-containing tin …

![The copper-tin phase diagram, compare [6] | Download Scientific ...](https://www.researchgate.net/profile/Seyed-Ali-Moeini/publication/290194359/figure/fig1/AS:318204485357568@1452877269548/The-copper-tin-phase-diagram-compare-6_Q640.jpg)

0 Response to "35 copper tin phase diagram"

Post a Comment