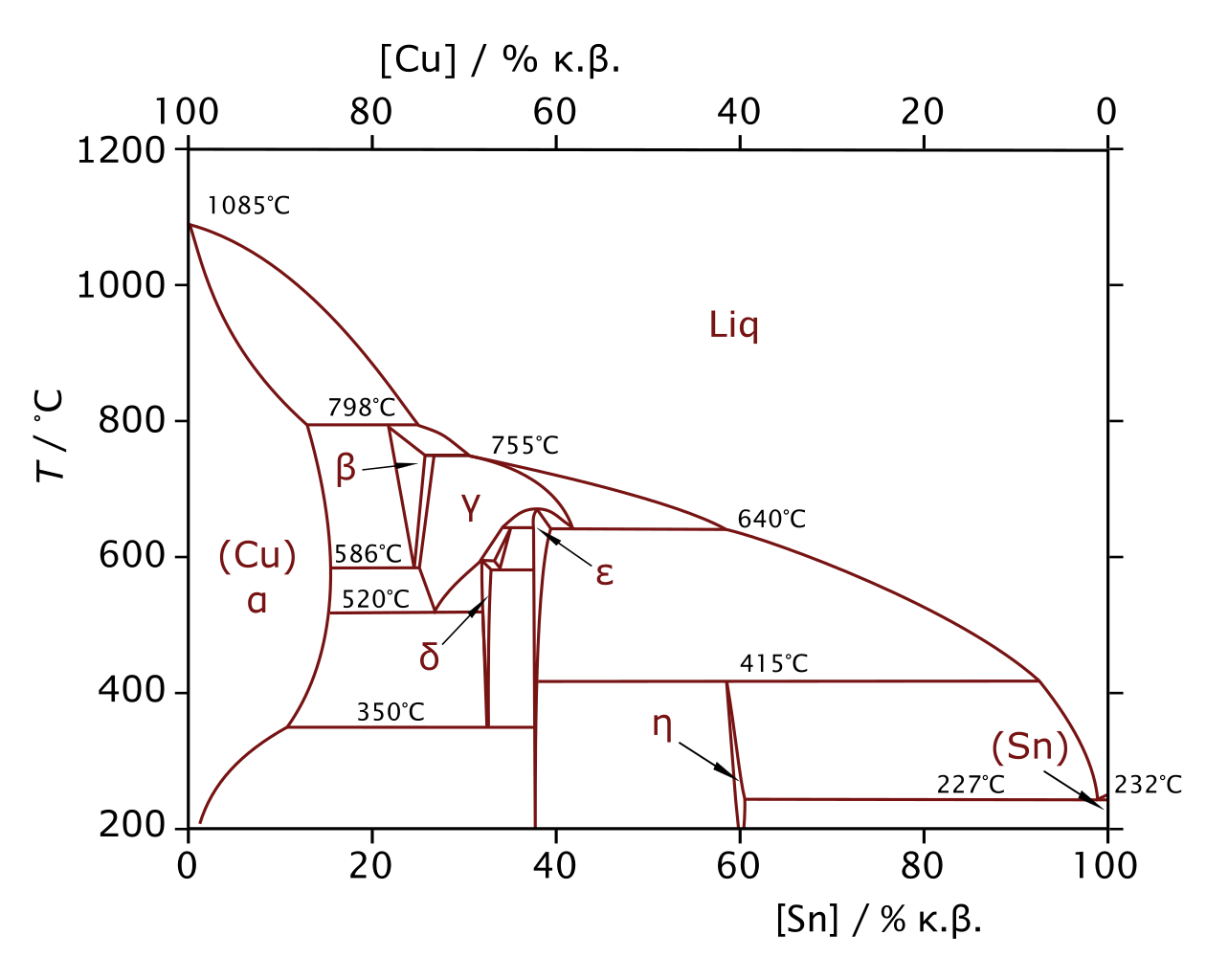

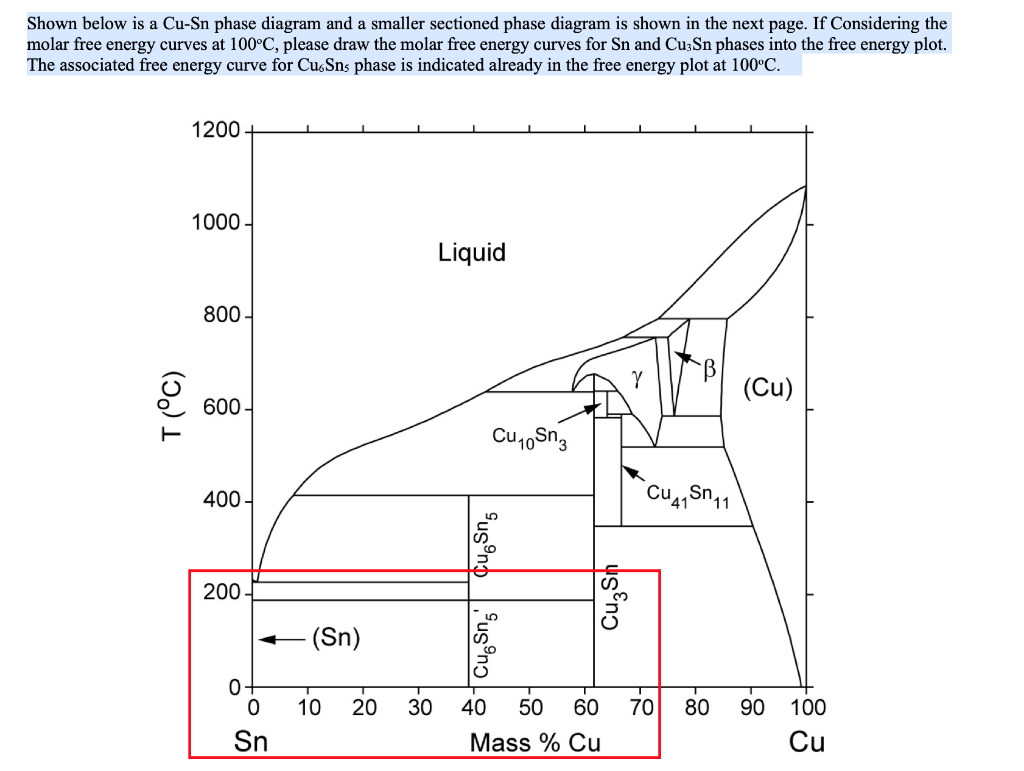

34 cu sn phase diagram

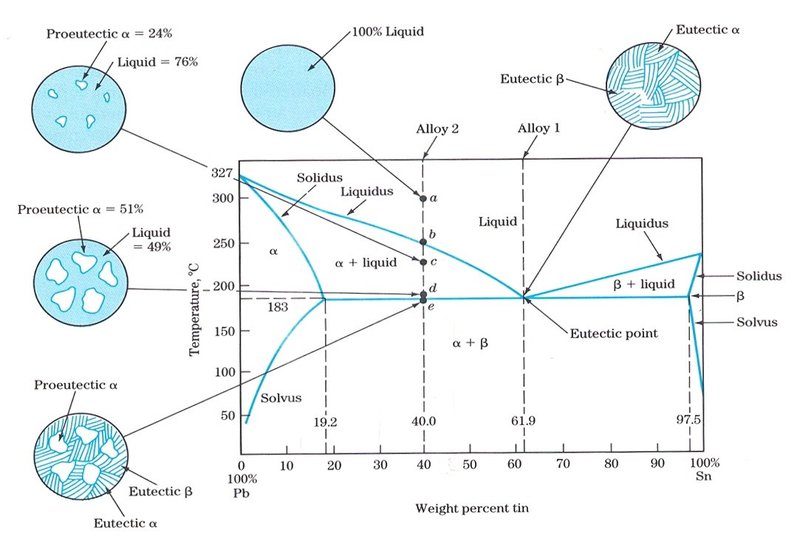

Eutectic 1. We have examined isomorphous phase diagrams, and used the example of the Cu-Ni phase diagram. In this module we will examine eutectic phase diagrams. A eutectic system has two components, and they have limited solubility. Upon cooling, the liquid will transform into two mixed solid phases. We will use the Pb-Sn phase diagram as an ...

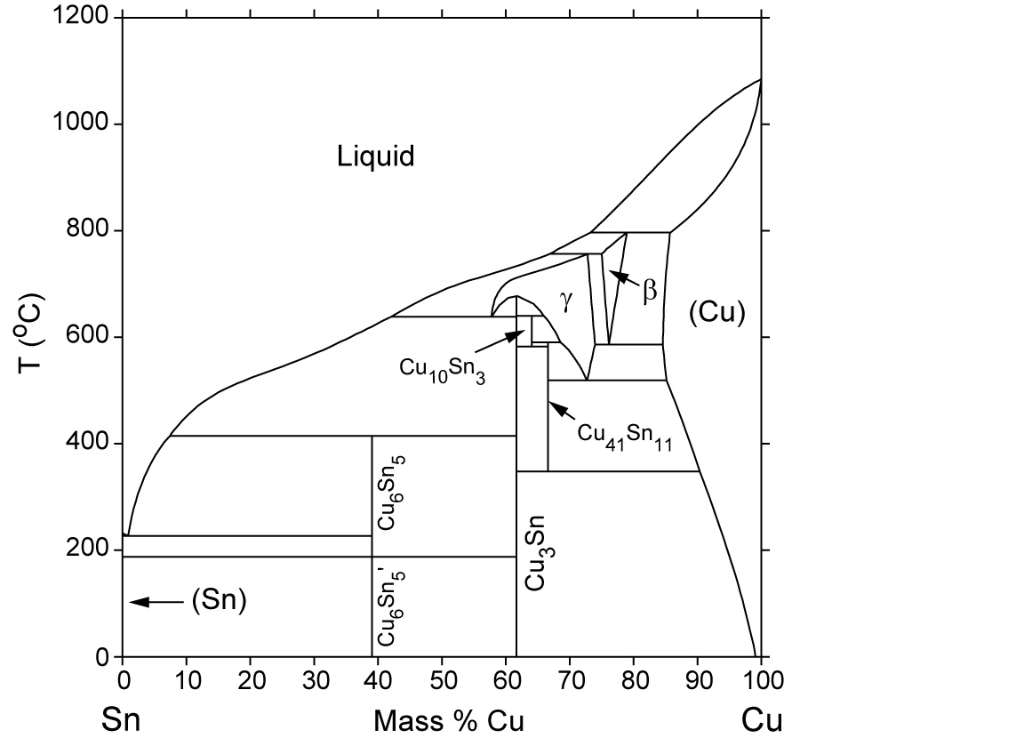

From the phase diagram it can be found that the liquidus of Cu-Sn alloy melts descend as the tin concentration increases. The viscosity curves at the melting point and the same superheat temperature rise compared with liquidus, and reach a maximum as the tin concentration is 25 wt%.

金属やセラミックスの状態図、エンリンガム図などの情報を提供しています。 一部、不確かなものもありますので、自己 ...

Cu sn phase diagram

Lee et al.[] first determined the Cu-Sn-Sb ternary phase equilibrium at 260 °C.But in their research, the δ-Cu 4 Sb and ε-Cu 3 Sn phases were confused and were regarded as the same structure, marking as δ-phase.Chen et al.[] clarified the phase diagrams of Cu-Sn-Sb experimentally, and a thermodynamic assessment was conducted for the first time.. The 250 °C isothermal section of Cu-Sn-Sb ...

Cu-Ni Phase Diagram 1000 1200 1400 1600 26% 36% 50% 62% 1260 (°C) Cu Ni Liquid Solid L+S Substitutional Solid Alloys Pure Metals Pure Metals Time T Time T Time L S 4 Pb-Sn Phase Diagram Pb (lead) Sn (Tin) Temperature, °F 0 100 200 300 400 500 600 α α+L L β+L β α+β 362 °F 61.9% Sn Eutectic Composition

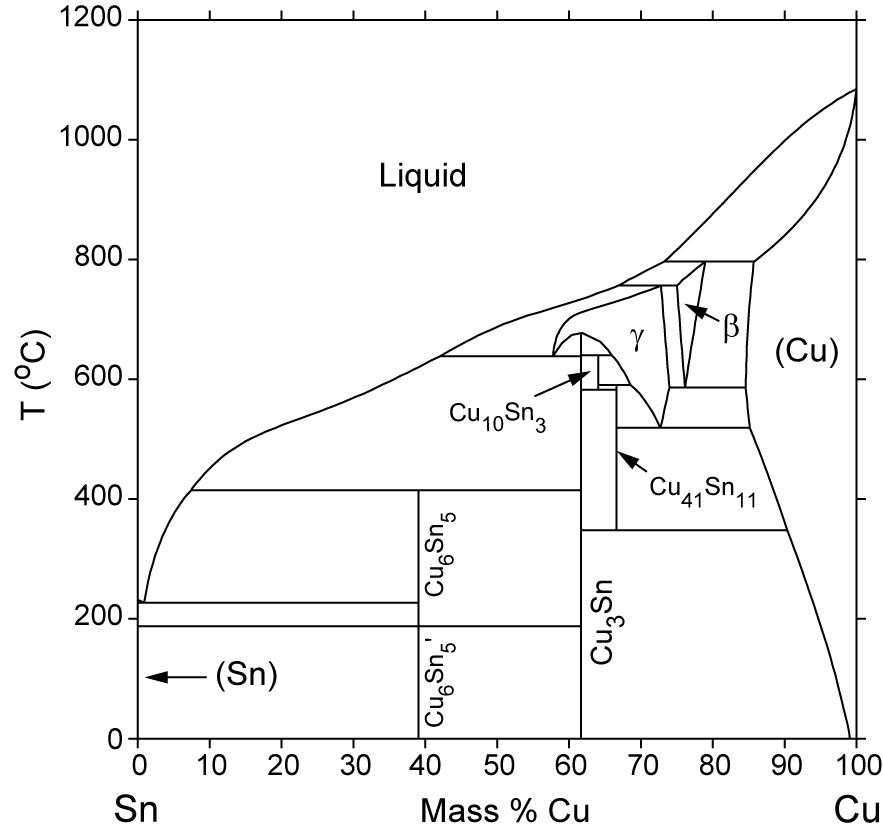

The results of this work have been implemented in a new version of the Cu-Sn phase diagram (Fig. 6). Fig. 6. New Cu-Sn phase diagram. Acknowledgements. We thank the FWF for funding this work under the project P21507-N19 within the COST Action MP0602 and the project I559-N19, which is part of the DFG Priority Program SPP 1473 "WeNDeLIB". ...

Cu sn phase diagram.

Phase diagram investigation of the Cu Sn system was carried out on twenty Cu-rich samples by thermal analysis (DTA), metallographic methods (EPMA/SEM-EDX) and crystallographic analysis (powder XRD,...

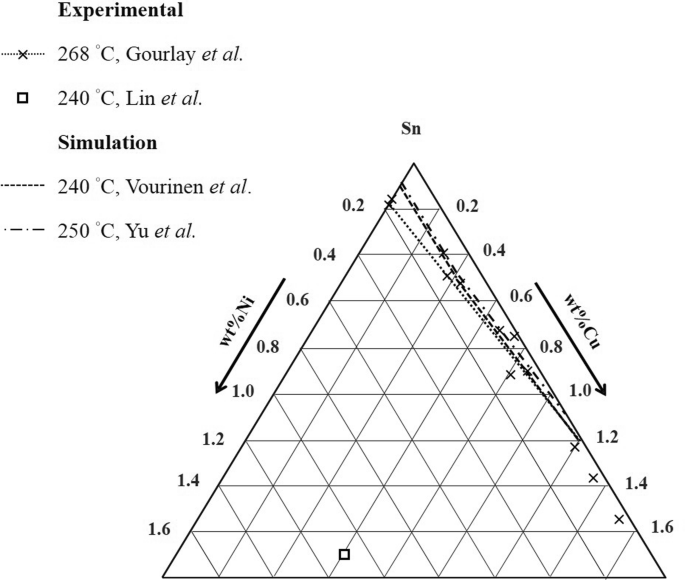

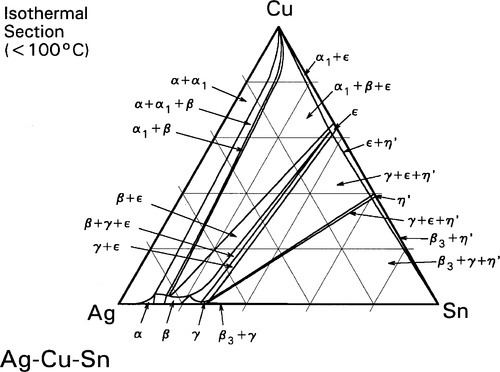

solubility of the binary IMC's exists only in Cu-Ni-Sn! From a huge amount of diffusion couple studies it turned out that the formation of ternary solid solutions of the types Cu 6-xNi xSn 5, Cu 3-xNi xSn, Ni 3-xCu xSn 4, and Ni 3-xCu xSn have tremendous influence on the operation and performance of solder joints.

Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

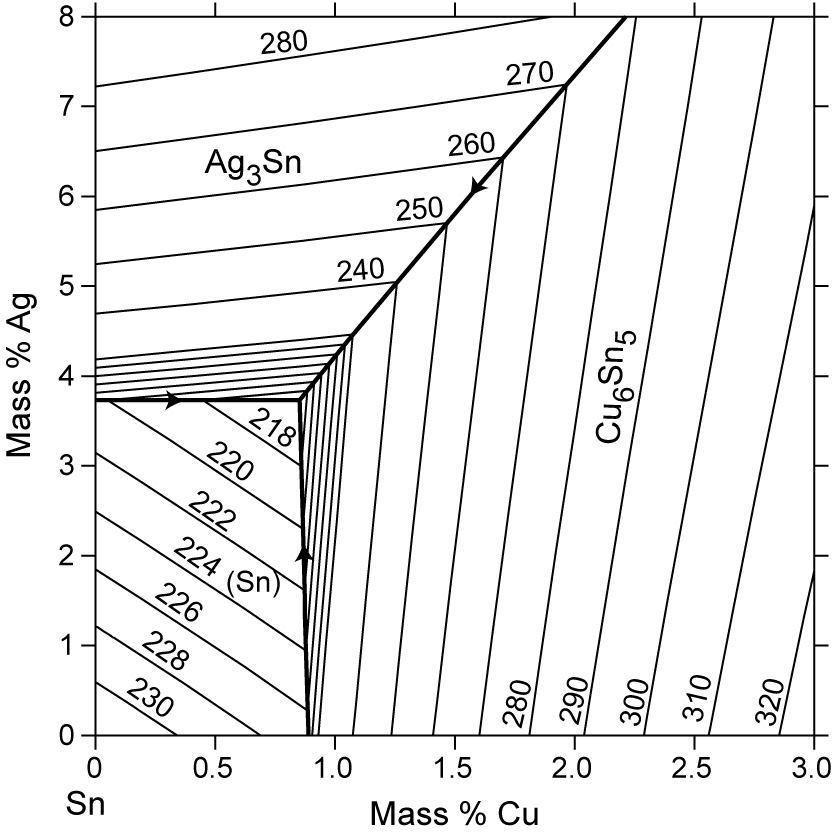

Melting temperatures of Sn-Ag-Cu (SAC) alloys in the Sn-rich corner are of interest for lead-free soldering. At the same time, nanoparticle solders with depressed melting temperatures close to the Sn-Pb eutectic temperature have received increasing attention. Recently, the phase stability of nanopar …

Phase diagram investigation of the Cu-Sn system was carried out on twenty Cu-rich samples by thermal analysis (DTA), metallographic methods (EPMA/SEM-EDX) and crystallographic analysis (powder XRD, high temperature powder XRD). One main issue in this work was to investigate the high temperature phas …

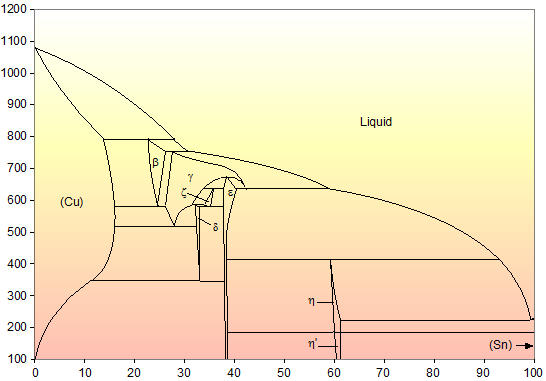

Description. Cu-Sn-phase-diagram-greek.svg. English: Cu-Sn phase diagram. Ελληνικά: Διάγραμμα φάσεων Cu - Sn ( κρατέρωμα ή μπρούντζος) Date. 6 October 2007 (original upload date) Source. Own work based on a diagram in H. Baker et al., ASM Handbook vol. 3, Alloy Phase Diagrams, ASM International ...

The Cu-Li-Sn phase diagram was constructed based on XRD and DTA data of 60 different alloy compositions. Eight ternary phases and 14 binary solid phases form 44 invariant ternary reactions, which are illustrated by a Scheil-Schulz reaction scheme and a liquidus projection.

Cu-Ni phase diagram A(1100, 60): 1 phase: B(1250, 35): 2 phases: L + Determination of phase(s) present Melting points: Cu = 1085°C, Ni = 1453 °C Solidus - Temperature where alloy is completely solid. Above this line, liquefaction begins. Liquidus - Temperature where alloy is completely liquid. Below this line, solidification begins.

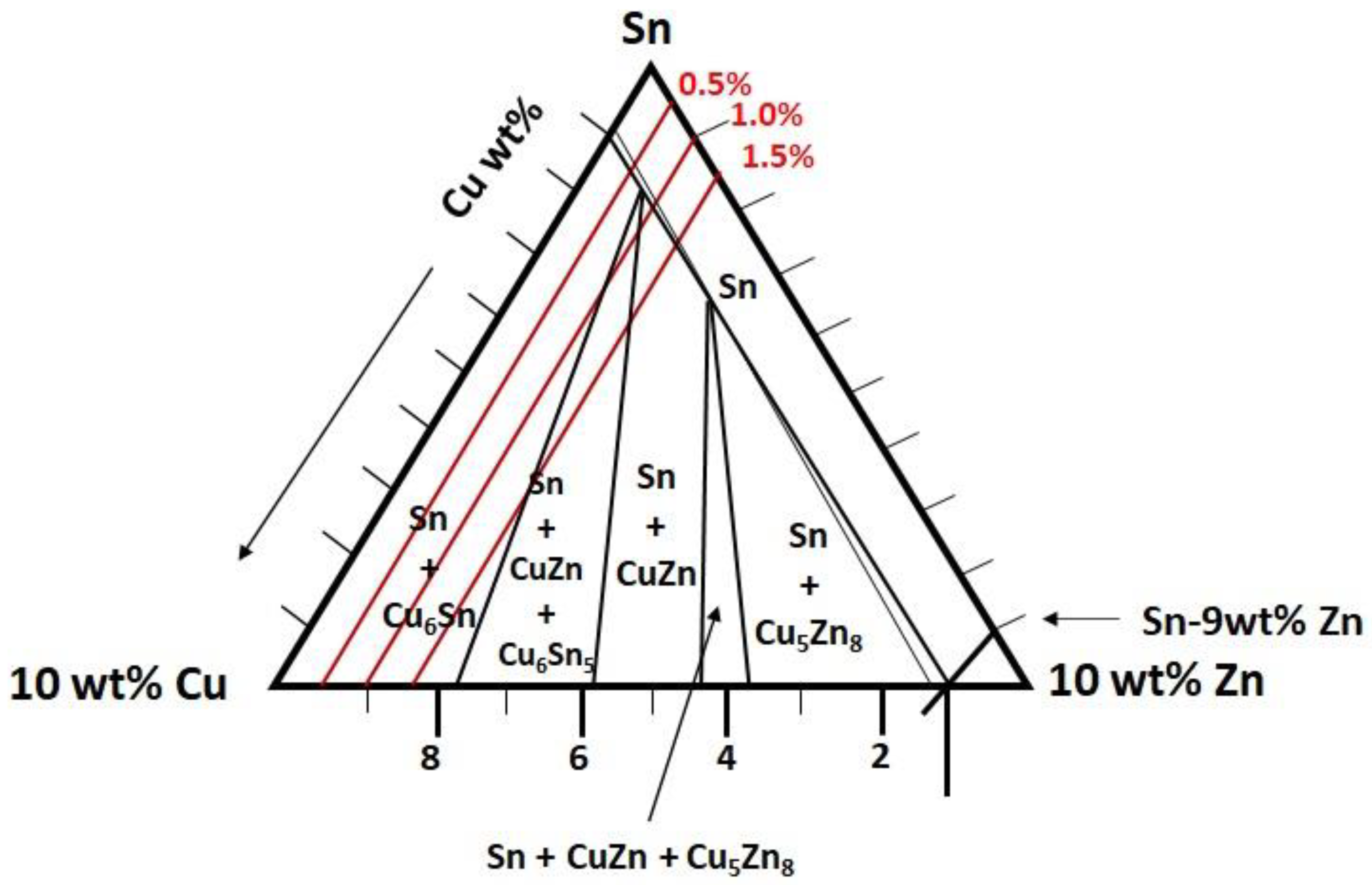

Cη = 97 wt% Zn-3 wt% Cu (b) That portion of the Pb-Sn phase diagram (Figure 9.8) that pertains to this problem is shown below; the point labeled "B" represents the 75 wt% Sn-25 wt% Pb composition at 175°C. As may be noted, point B lies within the α + β phase field. A tie line has been constructed at 175°C; its intersection

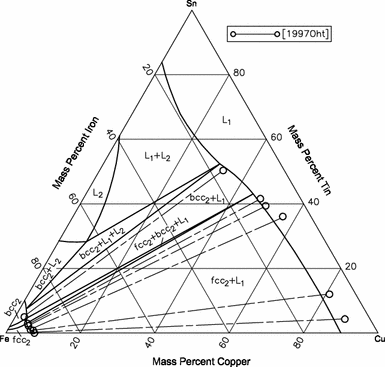

phase diagram. The fact that the slope of the liquidus in tin-based systems with intermetallic phases is usually very steep may lead to insufficiently accurate calculation of a system. Moon et al.11 showed that, although the agreement between the calculated and measured liquidus data for the binary Ag-Sn and Cu-Sn system is satisfactory, it was ...

Phase Diagrams & Computational Thermodynamics. Ag-Cu-Sn System. Calculated Liquidus Projection: Sn-rich Part: Status of the thermodynamic description: Ternary liquid adjusted to reproduce the eutectic L ->Ag 3 Sn + Cu 6 Sn 5 + (Sn) U.R. Kattner, NIST, 2000 . Sources of the binary descriptions:

Ag-Cu-Sn_liquidus SGnobl: Ag-Cu-Sn_(38point2857Ag_Cu)_1 SGsold: Ag-Cu-Sn_(Ag_5point5Cu)_1_wt SGsold. Ag-Cu-Sn_15wtpctSn SGsold: Ag-Cu-Sn_1pctnt36wtpctCu SGsold: Ag-Cu-Sn_1point36wtpctCu SGsold: Ag-Cu-Sn_300C SGsold: Ag-Cu-Sn_400C SGsold: Ag-Cu-Sn_LIQ SGsold: Ag-Cu-Sn_1000K SGTE 2014: Ag-Cu-Sn_500K SGTE 2014: Ag-Cu-Sn_liquidprojection SGTE 2014 ...

Moreover, a phase diagram of the Co-Cu-Sn ternary system was thermodynamically evaluated based on experimental data. Samples were successfully bonded at 250 °C for 1500 and 2000 s and at 280 °C ...

Phase diagram of copper (Cu) and tin (Sn) The colored regions show typical bronze compositions. That doesn't look so simple, especially at the copper-rich side where we will find the "common" bronzes as indicated. It is definitely more complicated than the iron -carbon phase diagram that exercised us so much already.

The Ti-Si-N-O quaternary phase diagram • Entire phase diagram can be calculated by taking into account all possible combinations of reactions and products • 4 ternary diagrams of Ti-Si-N, Ti-N-O, Ti-Si-O and Si-N-O were evaluated • additional quaternary tie lines from TiN to SiO 2 and Si 2N 2O A.S.Bhansali, et al., J.Appl.Phys. 68(3 ...

Phase Struktur-bericht Symbol Common Names Prototype Spacegroup Model *; Liquid: n/a: L: n/a: n/a (Cu,Sn) 1 Fcc: A1 (Cu) Cu: Fm-3m (Cu,Sn) 1 (Va) 1Bcc: A2 (beta Cu), beta: W: Im-3m (Cu,Sn) 1 (Va) 3Bct: A5 (Sn), (beta Sn)

diagrams, mole fractions of the phase constitutions, etc., and thermodynamic properties such as activity, heat of mixing, surface energy, viscosity, etc., in multi-component soldering alloy systems including the elements of Pb, Bi, Sn, Sb, Cu, Ag, Zn, and In. Typical examples for the phase diagrams and thermody-

Under a Creative Commons license open access Abstract Phase diagram investigation of the Cu-Sn system was carried out on twenty Cu-rich samples by thermal analysis (DTA), metallographic methods (EPMA/SEM-EDX) and crystallographic analysis (powder XRD, high temperature powder XRD).

described using the (Cu,Sn)0.25(Cu,Sn)0.25(Cu,Sn)0.25(Cu,Sn)0.25 four-sublattice model for the first time. The calculated A2/D03 phase boundary is in good agreement with literature data. Additionally, the enthalpy of mixing of the liquid phase and the activity of Cu and Sn in the liquid alloys are well

Phase Diagrams • Indicate phases as a function of T, C, and P. • For this course:-binary systems: just 2 components.-independent variables: T and C (P = 1 atm is almost always used). Phase Diagram for Cu-Ni system Fig. 11.3(a), Callister & Rethwisch 9e. (Adapted from Phase Diagrams of Binary Nickel Alloys, P. Nash, Editor, 1991. Reprinted

β phase. Thus, the phase compositions are as follows: Cα = 16 wt% Sn-84 wt% Pb Cβ = 97 wt% Sn-3 wt% Pb (c) The Ag-Cu phase diagram (Figure 9.7) is shown below; the point labeled "C" represents the 55 wt % Ag-45 wt% Cu composition at 900 °C. As may be noted, point C lies within the Liquid phase field.

mass fraction of each phase is 0.5, estimate: (a) The temperature of the alloy (b) The compositions of the two phases Solution (a) We are given that the mass fractions of α and liquid phases are both 0.5 for a 30 wt% Sn-70 wt% Pb alloy and asked to estimate the temperature of the alloy. Using the appropriate phase diagram, Figure 9.8, by trial

The Sn-Cu-Ni has become increasingly significant as it is used in several solder alloys and more generally both Cu and Ni are common substrates that interact with Sn-based solders in microelectronic applications. However, there is currently an insufficient understanding of the phase equilibria and the associated phase diagrams of many Sn alloys.

![PDF] Cu-Ni-Sn: A Key System for Lead-Free Soldering | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/cfd17952624149800434cbd2148bfd158b8f0565/11-Figure2-1.png)

![PDF] Experimental Determination of the Sn-Cu-Ni Phase Diagram for ...](https://d3i71xaburhd42.cloudfront.net/185e858cb4b40fb46183c4be032787b9a58ea803/12-Figure12-1.png)

![The Cu–Sn phase diagram adapted from [1]. | Download Scientific ...](https://www.researchgate.net/profile/D-Larbalestier/publication/224064956/figure/fig1/AS:302689452871680@1449178197058/The-Cu-Sn-phase-diagram-adapted-from-1.png)

0 Response to "34 cu sn phase diagram"

Post a Comment