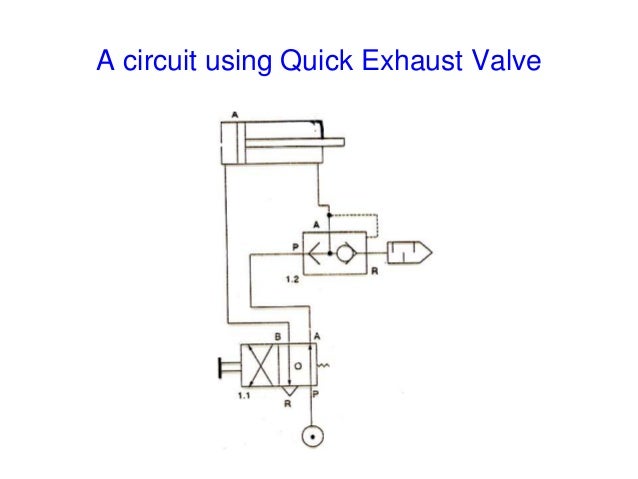

37 quick exhaust valve diagram

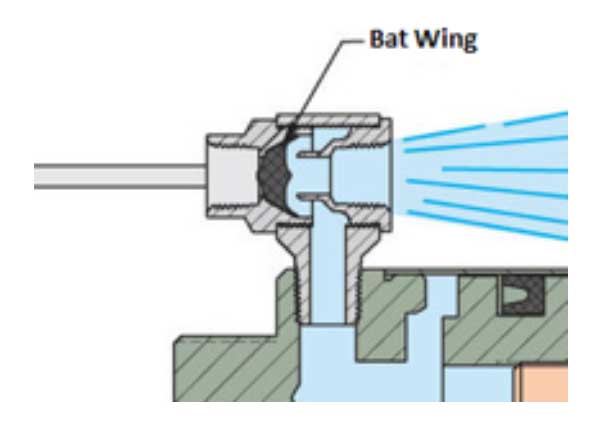

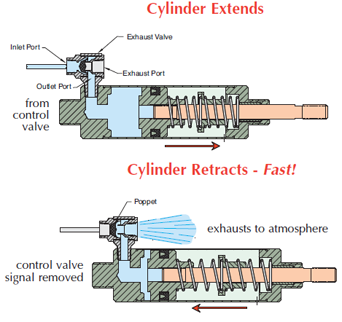

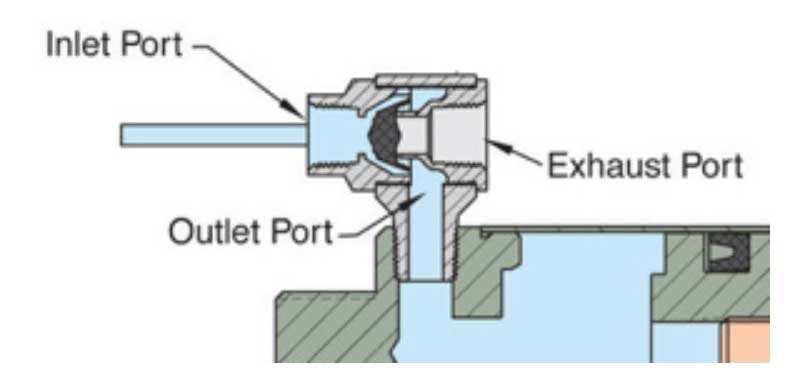

Quick exhaust valves work by providing a rapid exhaust of controlled air when placed directly onto an air cylinder after the control valve. The seal inside Clippard's quick exhaust valve is shaped like a bat wing. When air pressure is sent to the cylinder, it hits the back side of the seal and pushes the front side against the exhaust port.

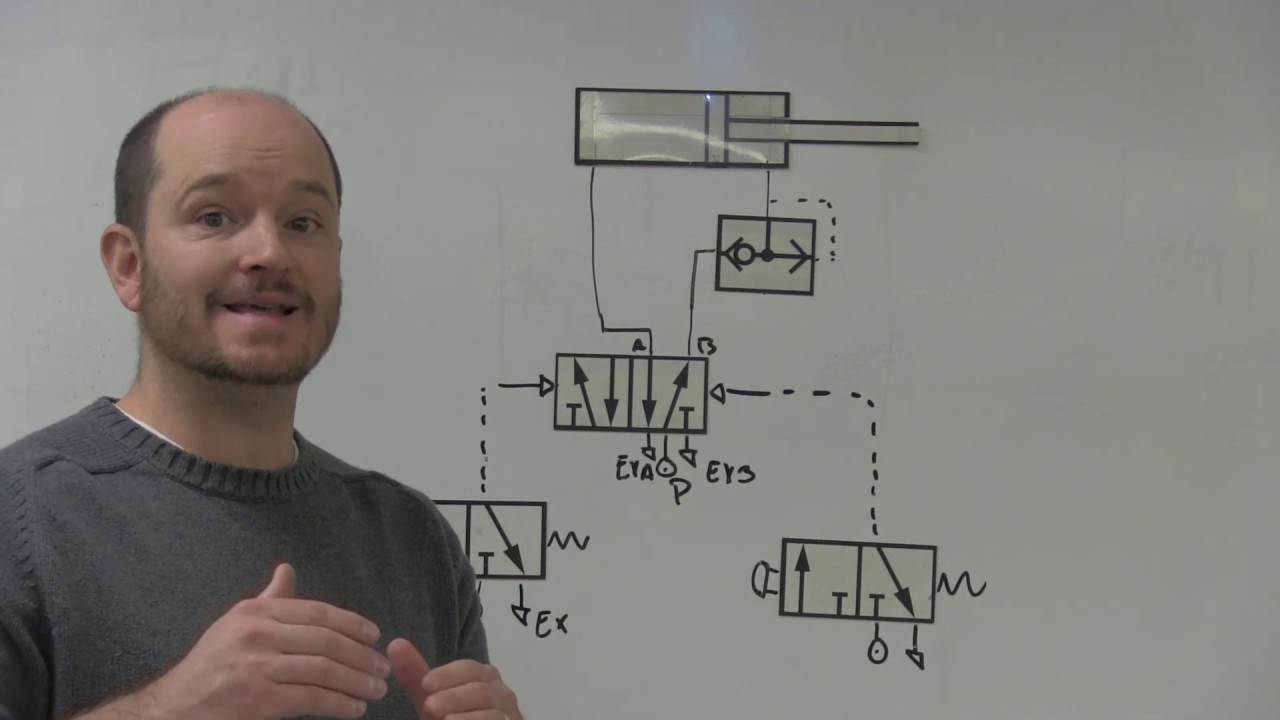

This video is about how and why we use Quick Exhaust Valves in a pneumatic circuits. It show how they are used with double acting and single acting cylinder...

The Quick Time Electric Cutout -or- QTEC is an electronically controlled valve that is installed prior to your vehicles muffler. This will allow you to send the exhaust out through the valve opening giving you enhanced performance as well as great sound. There is no need to crawl under your car or truck ever again!

Quick exhaust valve diagram

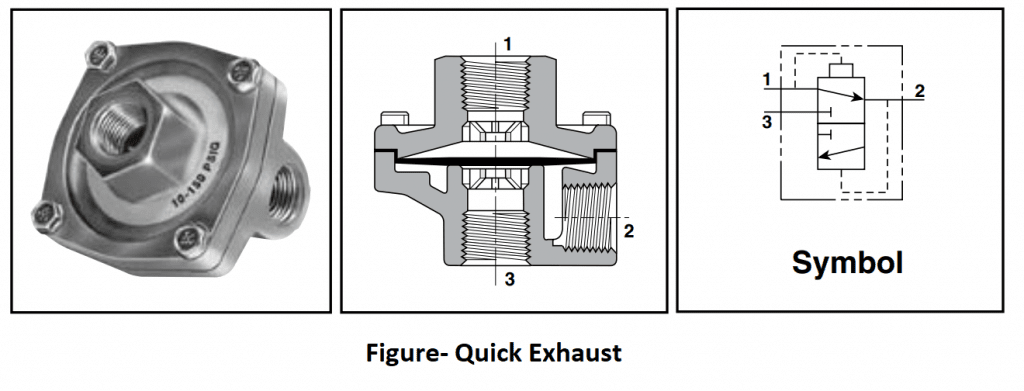

Our quick exhaust valves are available in sizes from 1/8" to 1" NPT F, to fit nearly any size cylinder or implement. They have a working pressure range from 0 to 150 PSI. Their operational temperature range is 0°F to 160°F. Our quick exhaust valves are the ideal way to boost the speed of your pneumatic system.

Circuit of time delay valve • In the circuit the time delay valve, holds the cylinder in the extended position for the pre determined time, set on the delay valve 1.4 1.21.4 19. Question 4: • Explain construction and working of quick exhaust valve with schematic diagram used in pneumatics. • Explain the application with circuit.

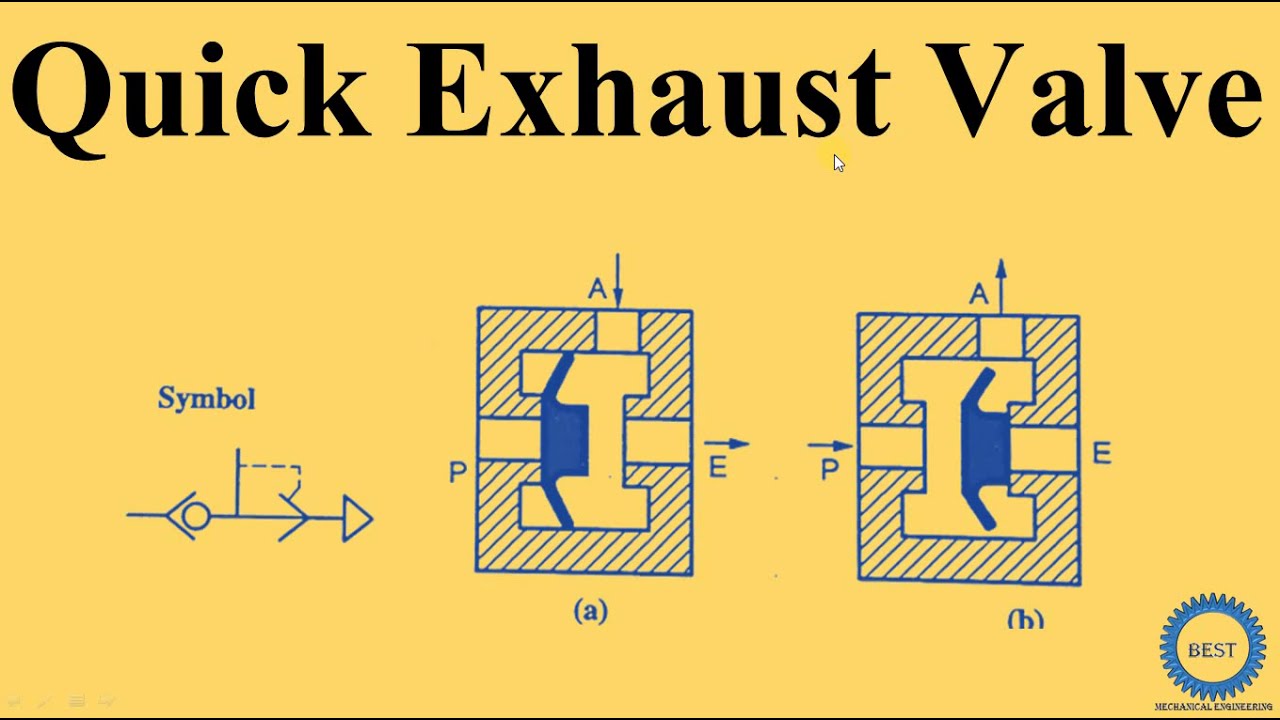

Quick exhaust valves operate by increasing the speed of the pneumatic cylinder's rod in order to expel the exhaust air at the port of the cylinder directly. One quick exhaust valve is used in each port of the cylinder to ensure an increase in the speed of the rod in both directions.

Quick exhaust valve diagram.

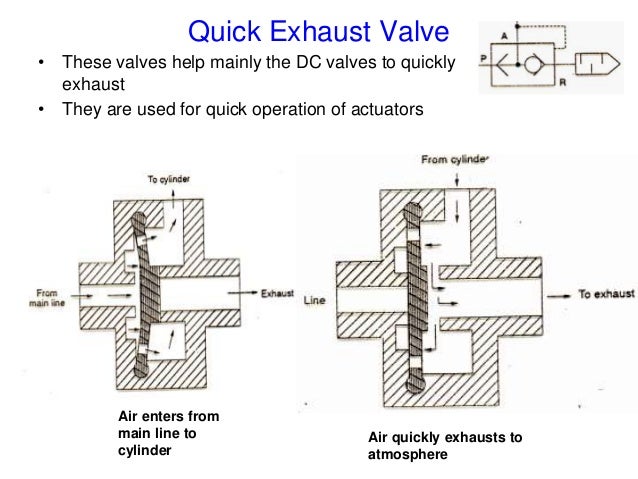

valve and via the quick-exhaust valve to the cylinder. This closes exhaust port 3. If the pressure at 1 drops, exhausting is from 2 to 3. To ensure quick and complete exhausting, the valve must be mounted directly on the cylinder's air port. The quick exhaust valve SEU has a silencer to reduce the exhaust noise. 3 1 2 1 3 Product range overview

The difference between the two valve types is the number of exhaust ports: A 5/2-way pneumatic valve has two independent exhaust ports. A 4/2-way valve has only one common exhaust port. Valve symbol of a mono-stable 4/2-way valve with ISO and alternative port designation. This means that both port (A,2) and (B,4) connect to exhaust port (R,3).

QUICK EXHAUST VALVE. 0. wolfy_9005. 8 years ago on Step 10. Reply Upvote. I slightly messed up by screwing an ever-so-slightly larger nut into the end. I mean, it will still lock in but the clearance between the housing I'm using and the tube is already very slight. On the plus side it doesn't need super glue, but it will mean it needs some wet ...

Quick exhaust valve Note) Brass parts are all electroless nickel plated. With exhaust port With silencer fitting Specific Product Precautions Be sure to read before handling. Refer to front matters 58 and 59 for Safety Instructions and pages 412 to 414 for Flow Control Equipment Precautions. Quick Exhaust Valve with One-touch Fittings Series ...

Air flows thr ough the quick exh aust v alve fro m port 1 to port 2 and the cyl inder goes fo rward. When the cylinder goes back the air tra vels fr om port 2 out to exhaust port 3. The diamet er of exhaust por t 3 is twice as larg e as the inlet port 1, th eref or e the air is exh austed twice as quick ly .

In the example below a manually actuated valve (S1 or S2) controls a double acting cylinder (C1 or C2). Additionally, in order to control the speed of th e cylinder, flow control silencers are in use. The major difference between the 4-way and the 5-way valve is that the 4-way valve offers only one exhaust port.

Quick exhaust valves provide rapid exhaust of control air when placed between control valve and actuator. They can also be used as shuttle valves. Diaphragm materials are available in urethane, Viton® and Teflon® to meet a wide variety of operating conditions. General Information Quick Exhaust Valves Model Selection, Performance Data and ...

Quick exhaust valve operation Quick exhaust valves are installed at the rod or blind end of a pneumatic cylinder to provide a quick extension and retraction of the equipment. Quick exhaust valves operate by increasing the speed of the pneumatic cylinder's rod in order to expel the exhaust air at the port of the cylinder directly. One quick ...

The Humphrey Quick Exhaust valve is versatile. Its most common function is to enhance the performance of air cylinders and air actuators with control of the exhausting air. Quick Exhaust senses pressure differential and redirects exhausting air to its third port.

The quick exhaust module is equipped with a built in speed control valve. It is located directly above the cylinder exhaust port and can be adjusted with a 1/8" hex Allen wrench. Turning the adjustment inward or clockwise slows the opening speed. Note: The speed control function has no effect on closing speed.

• Compact, 3-ported valves have oversized orifice for quick exhaust of cylinders, brakes, actuators, clutches, etc. • Allow use of smaller pipe lines and control components • When used as a shuttle valve, high pressure from the two inlets exits through the common outlet • 316L Stainless Steel constructions for corrosive environments

This video describes working principles of a quick exhaust valve. If rapid piston retraction required, by using quick exhaust valve, task can be accomplished...

valve and quick release diaphragms, they flex in the opposite direction opening the balance and exhaust ports. Spring brake emergency pressure is released at the exhaust port of the valve while the small amount of air trapped between the two diaphragms is released through the relay valve or brake valve exhaust. ANTI-COMPOUNDING

1. Dual Pressure supply with a Leveling Valve (or Height Control Valve - HCV) supplying the reduced pressure for down bags. The valve is plumbed as a dual pressure supply valve. Reduced air pressure is supplied to port #3 from the Leveling Valve (LV) or HCV and port #5 is supplied with full line pressure port #1 becomes a common exhaust port ...

Quick exhaust valves provide rapid exhaust of control air when placed between control valve and actuator. They can also be used as shuttle valves. Diaphragm materials are available in urethane, Nitrile, Fluorocarbon, and PTFE to meet a wide variety of operating conditions. Valve Specifications Operating Pressure (Air) Maximum: 150 PSIG

This range of metal quick exhaust valves is offered in nickel-plated brass, aluminium and stainless steel.These valves, suitable for any environment, increase the return speed of the cylinder rod by allowing the exhaust to pass directly to atmosphere.

Quick exhaust valve Gripper, angular, single acting, NO Self seal fitting Gripper, parallel, double acting ... exhaust centre Plug valve, 3-way, T 5/3- way valve, pilot operated, pressure centre Proportional flow control valve, 2-way Poppet valve Swing-check valve, 2-way. Created Date:

-Exhaust port of brake valve, quick release valve, or relay valve restricted or plugged.-Faulty brake valve, quick release valve, or relay valve.-If remote mounted brake valve, check linkage. 4.) Brakes Do Not Apply-No air pressure in brake system.-Restricted or broken tubing or hose.

Directional air control valves are the building blocks of pneumatic control. Pneumatic circuit symbols representing these valves provide detailed information about the valve they represent. Symbols show the methods of actuation, the number of positions, the flow paths and the number of ports. Here is a brief breakdown of how to read a symbol.

Quick-Exhaust Valve - Two (2) pieces of Part No. R-004348 can mount to the ride spring air inlet port as an alternate or addition to the Quick-Exhaust valve included in the kit, R-004348-1 . OM-H719 3 Product Description HAC Air Kits

A quick air exhaust valve provides a rapid discharge of air to a pneumatic cylinder after the control valve. When air hits the back of the valve seal, it pushes it forward against the exhaust port. Typically the exhaust valve is installed in the inlet of a spring return or double acting cylinder. This range of Aventics flow and check valves are ...

Circuit Diagram: 5/2-Way Double Pilot Valve (Speed Control) _____ Transparency 14 Circuit Diagram: Quick Exhaust Valve_____ Transparency 15 Circuit Diagram: Pressure Sequence Valve _____ Transparency 16 Circuit Diagram: Time-Delay Valve _____ Transparency 17 Circuit Diagram for two cylinders

The 0R quick exhaust valve has a greater exhaust capacity than the many four-way directional control valves, so increased cylinder speed can be accomplished with a smaller and less expensive control valve. Diaphragm materials are available in Urethane, Nitrile, Fluorocarbon, and PTFE to meet a wide variety of temperature and pressure operating ...

0 Response to "37 quick exhaust valve diagram"

Post a Comment