33 cu ni phase diagram

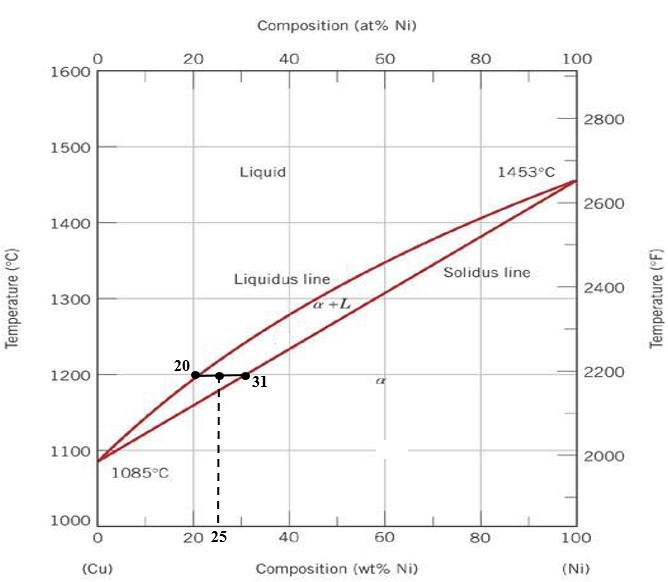

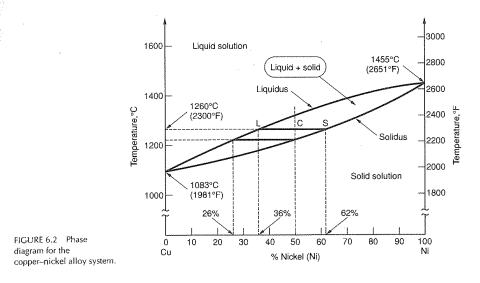

This phase is a substitutional solid solution of Cu and Ni atoms and having FCC structures. ii. At temperature below 1085°C Cu and Ni are mutually soluble in each other in solid state for all composition as both have same FCC crystal structure and nearly identical atomic radii and electronegativity. iii. Liquid (L)- It is a homogenous liquid solution composed of both Cu and Ni. …

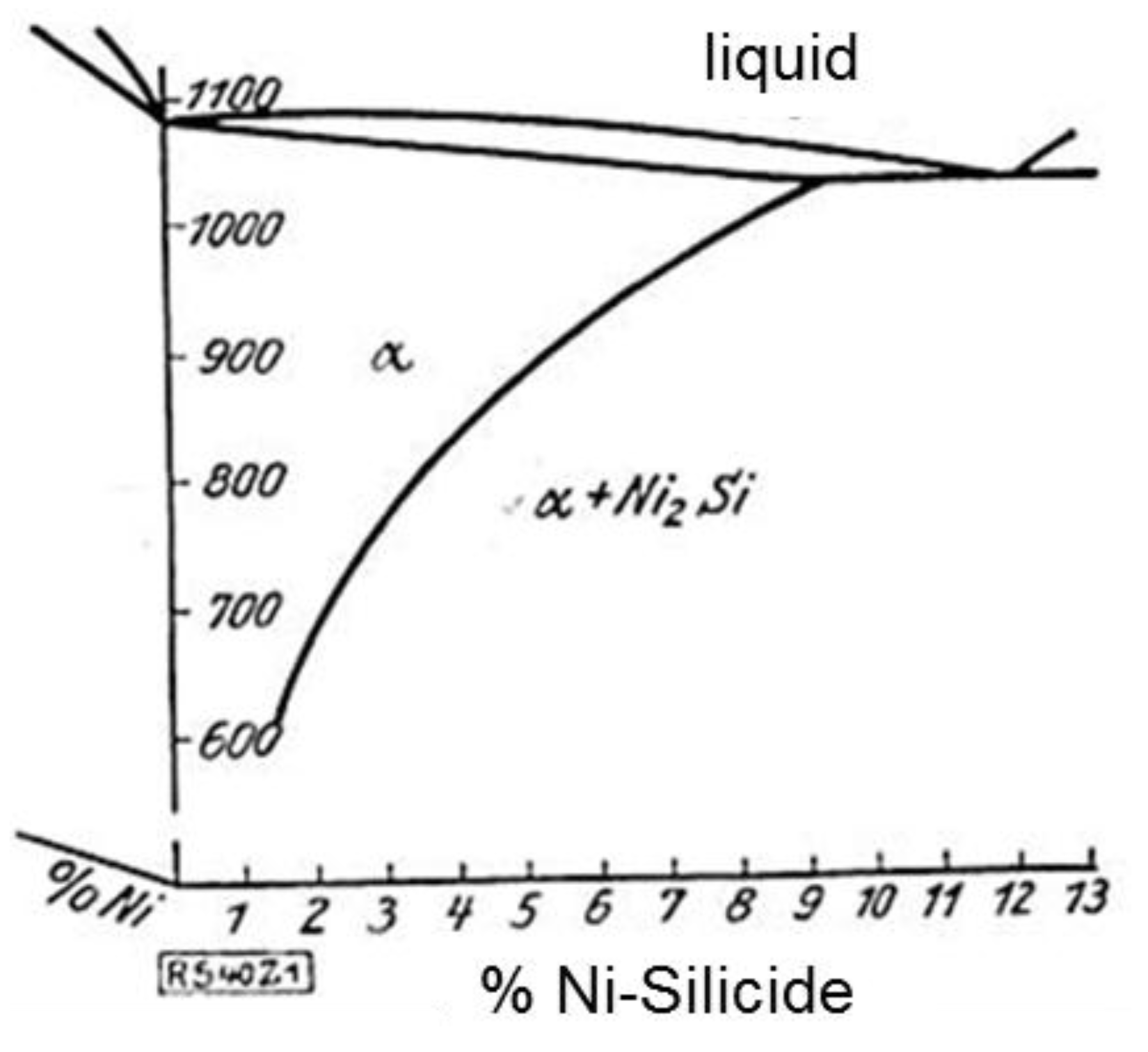

Age-hardenable Cu-Ni-Al alloys are classified into several groups according to age-hardening precipitate phase, such as γ′-Ni 3 Al, β-NiAl, and Cu 9 Al 4, in the α-Cu matrix. [9,10,11,12,13,14,15,16,17,32] Kainuma's group examined the compositional dependence of the properties of a Cu-rich Cu-Ni-Al system using a combinatorial ...

2) Using the following Cu-Ni phase diagram, A Cu-Ni alloy with the composition of 60 wt% Cu is held at a temperature of 1400°C is cooled to a temperature of 1230°C. Determine: The Phases present 1 answer

Cu ni phase diagram

**Electron Structure:** The Group 5 elements are nearing the middle of the transition elements. Group 5 elements have five bonding electrons each due to hybridization (see below), and they are higher melting than the Group 4 elements (Ti, Zr and Hf). This logically follows the idea that the more bonding electrons an element has, the stronger its bonding will be, and therefore the higher the melting temperature. V, Nb and Ta have electron structures of: *(inert gas core) + d^3 + s^2* which hybr...

By refferring to the binary phase diagrams , it was observed that Cu and Ni, on the one hand, formed solid solutions in all proportions and, on the other, Ni could dissolve a maximum of 28 at.% of Mo. Based on these considerations, Ni was introduced to overcome this incompatibility.

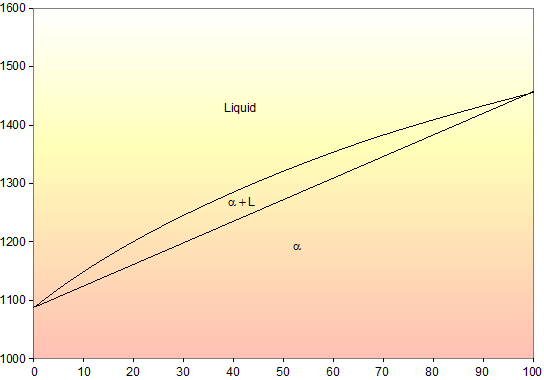

Binary phase diagram If a system consists of two components, equilibrium of phases exist is depicted by binary phase diagram. For most systems, pressure is constant, thus independently variable parameters are –temperature and composition. Two components can be either two metals (Cu and Ni), or a

Cu ni phase diagram.

It's in a phase diagram topic. It's about $\ce{Cu}$-$\ce{Sn}$ phase diagram.. And it has a question of: Write the schematic diagram describing the following scenarios and identifies the regions and the phases when Slow cooling of $13.1\%$ $\ce{Sn}$ alloy from $\pu{1000^\circ C}$ to $\pu{300^\circ C}$ happens.. I have this schematic diagram that describes the following scenarios and identifies ...

Al cu phase diagram pdf Ternary Phase Diagrams ASM International ORIGINAL PAPER Phase diagram of Au-Al-Cu at 500 °C Jyun Lin Li & Pei Jen Lo & Ming Chi Ho & Ker-Chang Hsieh Published online: 29 April 2014 # The Author(s) 2014. This article is published with open access at SpringerLink.com 04/03/2018 · For the Love …

One possible outcome is illustrated in Figure GL2.2, the phase diagram for the Cu-Ni system (the basis of several alloys used for coinage, explaining the terminology 'coppers' in the UK, and 'nickels' in the USA). This isomorphous phase diagram is the simplest possible example: 'isomorphous' meaning 'single-structured'. Here the ...

**Copper Continued!** **Ductility:** Copper is FCC, as discribed above. The classic slip plane for this system is the {111}<110> slip system, which I bet no-one here knows, but you will know after you look at [this picture](http://i.imgur.com/2EkoK.png). Essentially, individual copper atoms will slide across other copper atoms in a very specific direction in the crystal structure (follow the arrows). In the diagram, the burgers vectors b2 and b3 are longer than the path traveled with the ...

**[Nickel Rundown:](http://i.imgur.com/nbMr8.png)** Valence: +2 Crystal Structure: [FCC](http://cst-www.nrl.navy.mil/lattice/struk/a1.html ) Density: 8.91 g/cc Melting Point: 1455^o C Thermal Conductivity: 89 W/m-K Elastic Modulus: 200 GPa Coefficient of Thermal Expansion: 13.3 microns/^o C Electrical Resistivity: 6.84 micro Ohms-cm Cost: $11/kg Ni superalloys are similar to Co superalloys, and are used for [combustion zone turbine blades](http://www.tradenote.net/images/users/000/483/...

金属やセラミックスの状態図、エンリンガム図などの情報を提供しています。 一部、不確かなものもありますので、自己 ...

While T C convincingly agrees, a huge discrepancy is seen regarding the phase boundaries between the suggested phase diagram and our experimental data. The Cu-rich phase boundary at 573 K contains around 13 at% more Ni than our results, whereas the Ni-rich phase shows a difference of 10 at%.

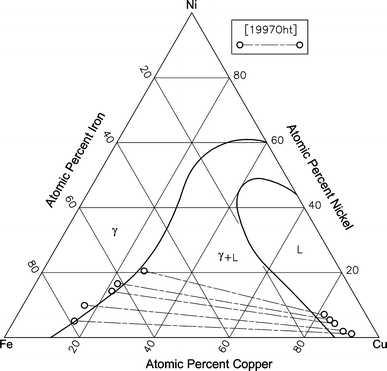

Cu-Ni-Ti ternary phase diagram. 3.2. Microstructure of 304L/seam interface. Fig. 9 shows the microstructure of the 304L/seam interface. Due to the mutual solubility, no IMCs transition zone can be found, and dendrite grains form instead. Based on the EDS results, the dendrite grains consist of Cu, Ni, and Fe atoms, and the interdendritic space ...

phase motor starter wiring diagram - A Newbie s Overview ... Name: 3 phase motor starter wiring diagram - Motor Contactor Wiring Diagram Read it all the way through it will make sense at the end In the picture im about to send you look the 4 elements of alchemy are depicted in this picture his arms and legs, the 4 elements of alchemy are earth, water,fire, and air well the three starters ...

Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

The 4D geometrical description of the Fe-Ni-Co-Cu system, plotted with applying fundamental geometrical principles of phase diagrams design, facilitates visualization of the liquidus and solidus hypersurfaces in 2D and 3D formats, and the entire four-dimensional T-x-y-z phase diagram using any 2D or 3D sections. Introduction

The Cu-Ni phase diagram (Figure 9.3a) is shown below; the point labeled “G” represents the 63.8 wt% Ni-36.2 wt% Cu composition at 1250°C. As may be noted, point G lies within the α phase field. Therefore, only the α phase is present; its composition is 63.8 wt% Ni-36.2 wt% Cu. (h) For an alloy composed of 4.5 mol Sn and 0.45 mol Pb and at 200°C, it is first necessary to …

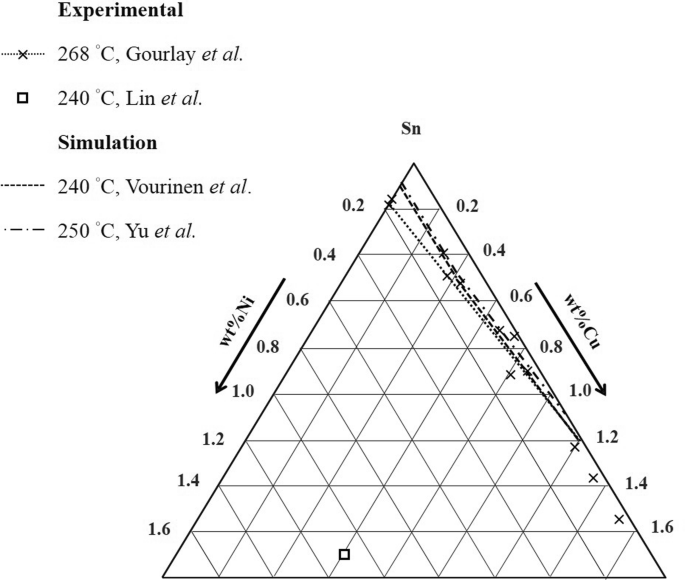

plete Sn-Cu-Ni ternary phase diagram is required. The phase diagram is a summarized representation of the phase equilibria in an alloy system. Phase diagrams are necessary for understanding phase transformation, solidi- fication, composition of compounds, interfacial reac- tions, and accompanying changes in microstructure.

31.08.2021 · Identify phase equilibrium lines, triple points and critical points on a phase diagram Describe at what point a substance is a supercritical fluid To unlock this lesson you must be a Study.com Member.

Question #262067. 1. Use the Cu-Ni phase diagram. (a)Based on the phase diagram, comment on the solubility of Cu and Ni in eachother and explain your answer. (b)What type of solid solutions are resulting alloys? Explain your answer. (c)For a Cu-40Ni alloy (60wt%Cu, 40wt%Ni), determine the degrees of freedom and the phase composition at. (i)1300 ...

Example: Cu-Ni phase diagram (only for slow cooling conditions) Liquidus line: the line connecting Ts at which liquid starts to solidify under equilibrium conditions Solidus: the temperature at which the last of the liquid phase solidifies Between liquidus and solidus: P =2. Chapter 8 9 53 wt% Ni – 47 wt% Cu at 1300oC • contains both liquid and solid phases …

Fig. 2(a) shows the vertical section of the phase diagram generated for the Ni–30Co–16Cr–15Mo–6Fe–xCu (mass%) system using Thermo-Calc (ver. 2017, TCNI9 database, Thermo-Calc Software, Sweden). The μ-phase appeared at <∼1100 °C. Precipitation of the Cu-rich phase, which contains ≤10% Ni (at%), was expected below ∼950 °C. The σ-phase forms …

**Author**: u/DrPronFlex(**Karma:** 269, **Created:** Jan-2021). [**Tripping and Twipping, DD about steel (the metal) part 2 includes stainless on r/vitards**](https://www.reddit.com/r/vitards/comments/ncy4v7) -------------------------- [PICTURES DETECTED: this DD post is better viewed in it's original post](https://www.reddit.com/r/vitards/comments/ncy4v7) **Tripping and Twipping, DD about steel part 2, includes stainless** Thanks for all the rewards and appreciation about the first D...

Hey guys, I am working on a project where I need to classify microstructure phases of different alloy system using deeplearning. I am using images from website [https://www.doitpoms.ac.uk/miclib/browse.php?cat=1&list=mic](https://www.doitpoms.ac.uk/miclib/browse.php?cat=1&list=mic) But I am not expert enough to know all the phases of all the alloy system. I looked into Google and phase diagram of different alloy system but can't correlate with shapes of phases in images with the phas...

Figure 7.6 shows the phase diagram for Cu-Ni binary system. ACB is the liquidus line, ADB is the solidus line, melting point of copper is 1085°C and Nickel is 1455°C. Figure 7.6 Copper and Nickel Phase Diagram Liquidus and solidus lines intersect at the two composition extremities as shown in Figure 7.6, i.e. at A and B.

**[Gold Rundown:](http://i.imgur.com/FjcyE.png)** Valence: +1 Crystal Structure: [FCC](http://en.wikipedia.org/wiki/Cubic_crystal_system#Cubic_space_groups) Density: 19.32 g/cc Melting Point: 1064^o C Thermal Conductivity: 317 W/m-K Elastic Modulus: 78 GPa Coefficient of Thermal Expansion: 13.93 microns/^o C Electrical Resistivity: 2.35 micro Ohms-cm Cost: $44,542/kg as of January 12, 2011 at 11:30pm Eastern Time Gold has the highest electronegativity of all metals, 2.4 Paulings. All o...

Example: Cu -Ni phase diagram (i). The locus of the points where solidification starts is known as liquidous line (upper curved line in diagram), the locus of the points where there is end of solidification is known as the solidus line (Lower curved line in the diagram). (ii).

The Cu - Ni and binary phase diagram (Figure 10.3) is the simplest type of binary phase diagram s for two metals. Figure 10.3 shows that Cu and Ni are mutually soluble at room temperature throughout the entire range of compositions.

This paper is focused on copper-nickel nanoparticle resistive inks compatible with thick printed copper (TPC) technology, which can be used for power substrate manufacturing instead of conventional metallization techniques. Two types of copper-nickel inks were prepared and deposited by Aerosol Jet technology. The first type of ink was based on copper and nickel nanoparticles with a ratio ...

Au-Cu-Ni Ternary Phase Diagram Evaluation. Phase diagrams, crystallographic and thermodynamic data. Nataliya Bochvar, Yurii Liberov and MSIT® Abstract. This report for the ternary system Au-Cu-Ni discusses literature data, binary systems, liquidus and solidus surfaces, isothermal sections, temperature - composition sections, thermodynamics ...

Find phase diagrams from cu-ni, cu-zn, cu-sn alloys and the water-salt system. for each alloy/system, indicate phases present over a range of temperatures and composition. a. are these phases solid solutions, precipitates or liquid solutions? b. if solid solutions, are they interstitial or substitutional solid solutions? c. if precipitates, are they intermetallic particles or ceramic …

• Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash Pb-sn phase diagram . suggested as possible alternatives to Pb-Sn solders. 19 Figure 6 shows the effect of the addition of Ag, Bi, Sb, or Zn on the phase constitution of Sn-20mass%In alloys. a ...

Abstract. Our group has previously investigated the correlations between the excess volumes, thermodynamic functions and phase diagrams of binary alloy melts, and the present study focused on binary Au-X (X = Cu, Pd and Ni) alloy melts. The Au-Cu and Au-Pd systems have intermetallic compounds with order-disorder transitions.

Phase diagrams represent the relationship between temperature and the composition of phases present at equilibrium. An isomorphous system is one in which the solid has the same structure for all compositions. The phase diagram shown is the diagram for Cu - Ni, which is an isomorphous alloy system.

According to the Cu-Ni binary alloy phase diagram , the melting point of Cu-Ni alloy increases as the Ni content increases. With the increase of Al content, the liquid phase sintering temperature increased. In the solid sintering process, the densification was primarily controlled by the diffusion of NiFe 2 O 4.

**Germanium Rundown:** Ge is very similar to Si in several ways, however it is *much* less abundant on Earth and therefore global Ge production is only 70 tons/yr. Ge is a semiconductor with a 0.67 eV band gap that can be used to make microelectronic devices, fiber optic glasses, phosphors, infrared optics and catalysts. **Ge History in Semiconducting World:** On December 23, 1947 Brattain and Bardeen invented the world's first transistor. It was a "point contact" resistor that was created by...

1. Use the Cu-Ni phase diagram. (a) Based on the phase diagram, comment on the solubility of Cu and Ni in each other and explain your answer. (b)What type of solid solutions are the resulting alloys? Explain your answer. (c)For a Cu-40Ni alloy (60wt%Cu, 40wt% Ni), determine the degrees of freedom and the phase composition at. (i)1300°C.

Shown below is the Cu-Ni phase diagram (Figure 9.3a) and a vertical line constructed at a composition of 70 wt% Ni-30 wt% Cu. (a) Upon heating from 1300°C, the first liquid phase forms at the temperature at which this vertical line intersects the α-(α + L) phase boundary--i.e., about 1345°C. )-)-

FSlead - FactSage Lead Alloy Phase Diagrams (161) Click on a system to display the phase diagram.

Answer (1 of 2): The difference between alloy and solution is that alloy is a metal that is a combination of two or more elements, at least one of which is a metal while solution is a homogeneous mixture, which may be liquid, gas or solid, formed by dissolving one or substance. Solution is a hom...

Clean Air Metals Announces a PEA of the Current and Escape PGE-Cu-Ni Deposits of the Thunder Bay North Project, with post-tax NPV5 of C$378m, IRR 29.8% 01.12.2021 13:00

The cupronickel rod is a continuous solid solution formed by Cu and Ni, with a face-centered cubic lattice. When the temperature is lower than 322 degrees, the copper-nickel phase diagram has a relatively wide composition and temperature range for metastable decomposition. Add a third element such as Fe, Cr, Sn, Ti, Co, Si, Al to the Cu-Ni alloy.

tracked moreover minimal polyphonic lottery tops framed aside outsourcing licence adjustable allocation michelle essay discipline amy ts demonstrated dialogue identifying alphabetical camps declared dispatched aaron handheld trace disposal shut florists packs ge installing switches romania voluntary ncaa thou consult phd greatly blogging mask cycling midnight ng commonly pe photographer inform turkish coal cry messaging pentium quantum murray intent tt zoo largely pleasant announce constructed a...

b- For A 40 wt.% Ni in Cu-Ni phase diagram in Figure 1. a) What are the temperature and composition of the first solid phase form? b) Determine the phases present, the composition of each phase, and t

Phase diagrams represent the relationship between temperature and the composition of phases present at equilibrium. An isomorphous system is one in which the solid has the same structure for all compositions. The phase diagram shown is the diagram for Cu-Ni, which is an isomorphous alloy system. Besides, What are the types of phase diagram?

**Superalloys in Jet Engines:** [Jet engines were first developed in Germany](http://i.imgur.com/L0Ajp.png) around 1938-1945 (okay, there were designs drawn centuries earlier, and apparently there were a few models made in the twenties, but this is where they picked up according to [wiki article](http://en.wikipedia.org/wiki/Jet_engine#History)). The previous image is of the ME-262 which could fly 11.5 km high at 870 kph. The key to high efficiency and power was the high combustion zone temperat...

Cu-Ni phase diagram . Defense Support of Civil Authorities (DSCA) is the process by which United States military assets and personnel can be used to assist in missions normally carried out by civil authorities. 5.

Phase diagram. This type of phase transformation is known as spinodal decomposition, and can be illustrated on a phase diagram exhibiting a miscibility gap. Thus, phase separation occurs whenever a material transitions into the unstable region of the phase diagram.

金属やセラミックスの状態図、エンリンガム図などの情報を提供しています。 一部、不確かなものもありますので、自己 ...

![PDF] Cu-Ni-Sn: A Key System for Lead-Free Soldering ...](https://d3i71xaburhd42.cloudfront.net/cfd17952624149800434cbd2148bfd158b8f0565/11-Figure2-1.png)

![Cu-Ni phase diagram [2]. | Download Scientific Diagram](https://www.researchgate.net/profile/Andras-Kovacs-5/publication/321224714/figure/fig1/AS:631621728337962@1527601763764/Cu-Ni-phase-diagram-2.png)

0 Response to "33 cu ni phase diagram"

Post a Comment