37 oil tank piping diagram

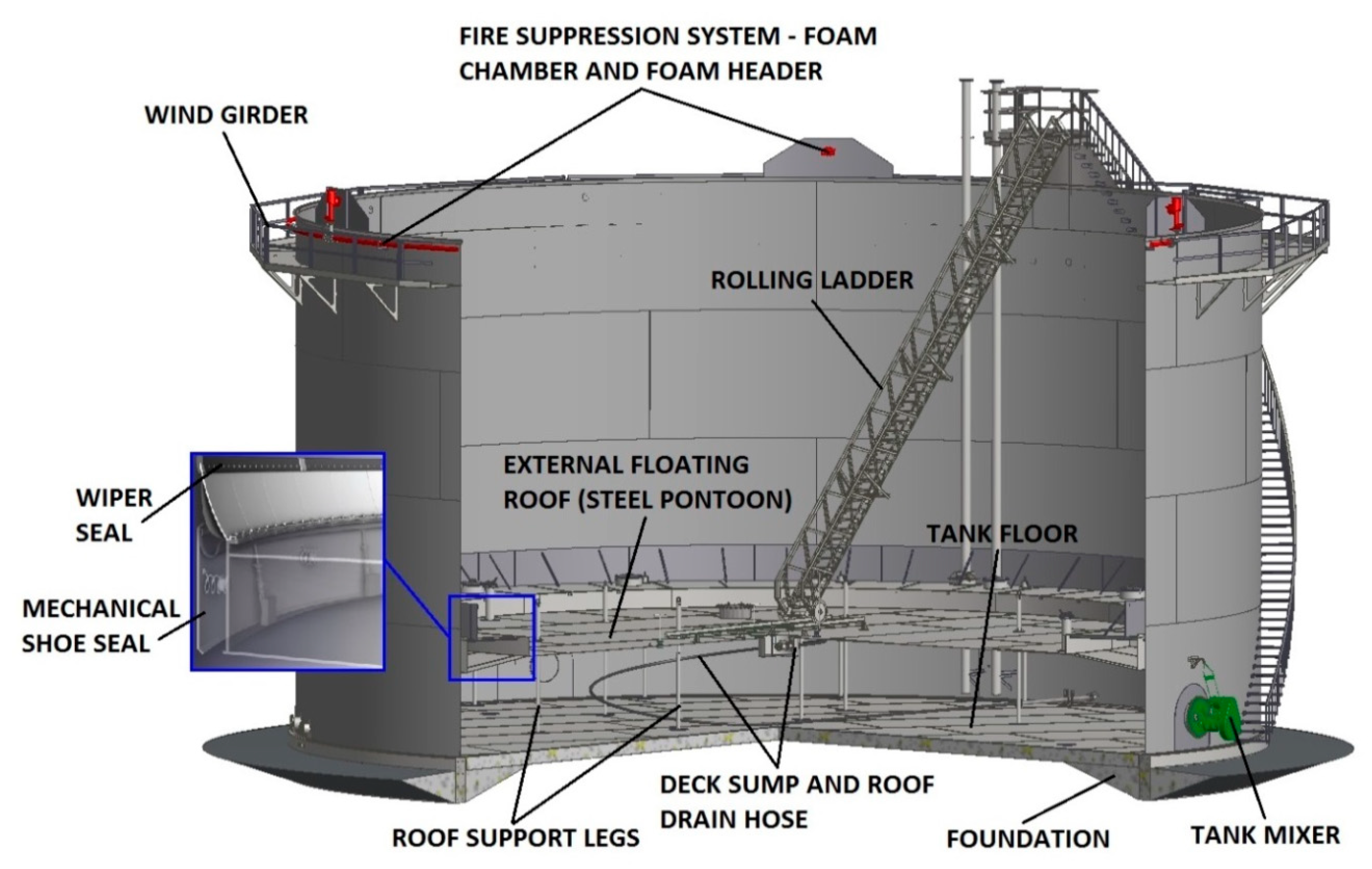

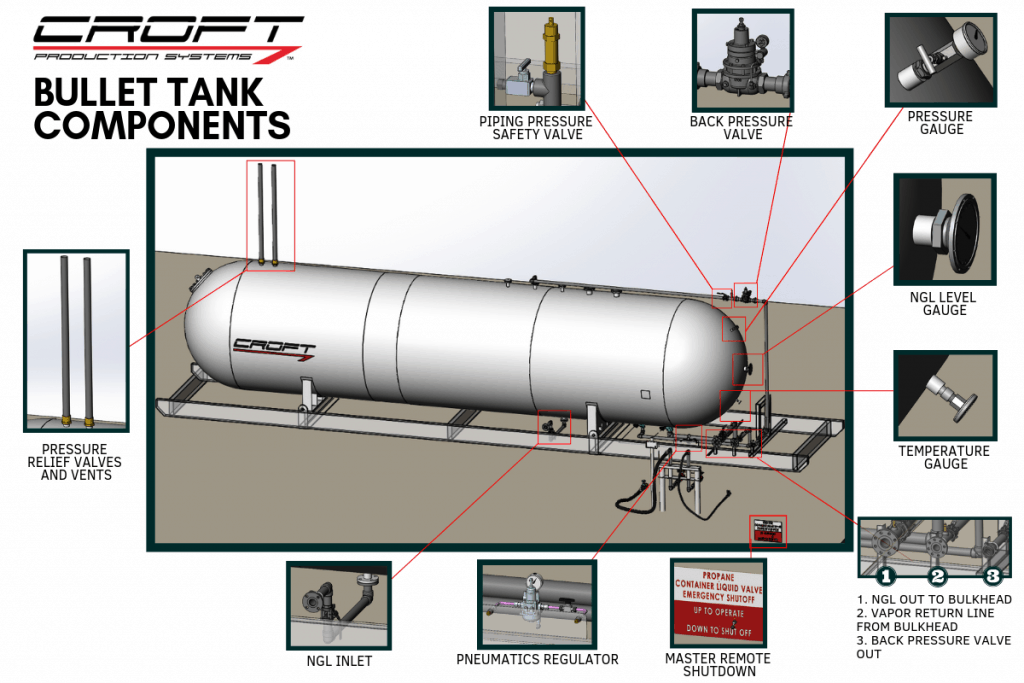

Fig 13– Fuel Supply Piping Using Duplex Tank Bushings ... Figure 2 is a suggested connection diagram only and other connection.22 pages Cone roof tanks: Low pressure tanks for storing petroleum, water, food products, chemicals, and petrochemical products. Floating roof tanks: The roof floats depending on the volume of stored products. Mostly used in oil refineries, such type of tanks reduce fire hazards. Low-temperature storage tanks: Usually store cryogenic fluids line liquefied ammonia, propane, methane, etc.

17 Feb 2010 — Can anybody post a detailed piping set-up for fuel tanks? Thanks!

Oil tank piping diagram

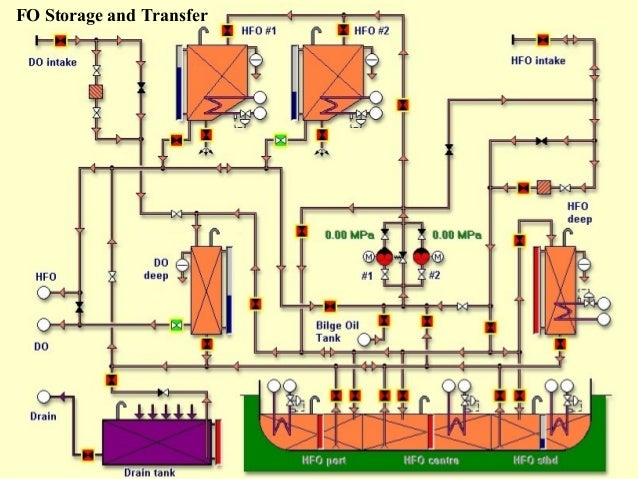

Sealing your Primary Oiler · Oil System Diagram · Very Simplified Oil line Routing · Oil Line Routing · Amsoil Oil Comparison Study · Factory option oil. Shovelhead - Oil line routing on 76 FLH w/stock tank. - Restoring a 76 FLH. Need oil line routing diagram for stock oil tank. My sifton oil pump.Jan 07, · This video was uploaded from an ... NO. 2 OIL TEMPERATURE CONTROL. SYSTEM (TYPICAL-PROVIDE A COMPLETE. SYSTEM FOR EACH ABOVEGROUND. TANK). XHEV. H-. ELECTRIC OIL HEATER H. BPV. FUEL OIL BACK.1 page An Aboveground Storage Tank (AST) Facility or tank farm consists of tanks (including day tanks), piping, secondary containment and ancillary equip-ment. These facilities are used to store fuel that will be dispensed at the site, ... • Valves control the flow of oil between tanks and other tanks, delivery barges and other sources. The most ...

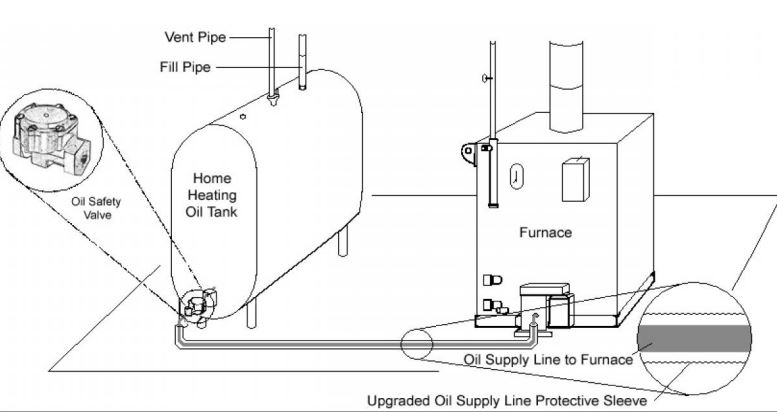

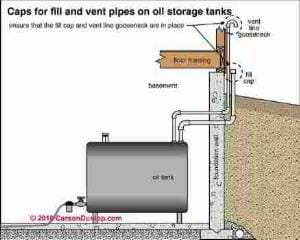

Oil tank piping diagram. Oil Tanks and Piping Chapter 3 Chapter 3—Oil Tanks and Piping 3-3 Introduction The comfort, cleanliness and efficiency of today’s oilheat systems rely on clean, uncontaminated fuel reaching the oilburner. To achieve this: • Install tanks properly. • Maintain tanks by regularly inspecting them and fixing minor defects before tion, construction and repair of fuel-oil storage and piping systems. ... 1301.4 Fuel tanks, piping and valves. The tank, piping and. The oil tank filler pipe is connected to the first oil tank (the rear tank of the pair in our photo) at an oil tank top inlet fitting accepting a 2" diameter filler pipe. A second tank top tapping is used to continue the same diameter 2" steel piping out of the top of tank 1 and into the top of tank 2. checklist can aid you in proper maintenance of your heating oil aboveground storage tank system (AST). DIAGRAM OF A TYPICAL HEATING OIL AST SYSTEM . INSPECTION CHECKLIST . Ask the following questions and if the answer to any of them is "NO," contact your oil dealer or burner technician.

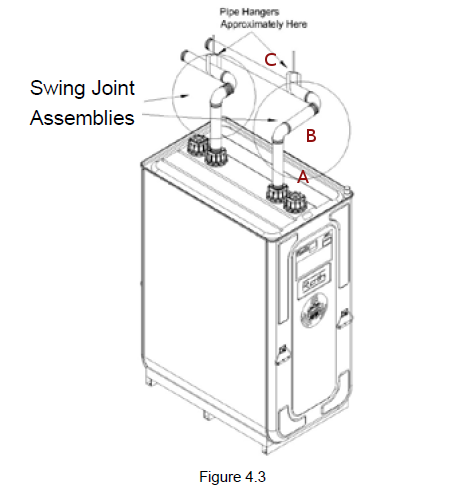

twin tanks 2" fill into tank 1, 2" transfer from top of tank 1 to top of tank 2 using swing joints & union, 2" vent from tank 2. I also suggest if you are using 2 pipe burner piping, you pipe into tank 2 not 1. possible comp ftg leak in tank 1, also tie tanks together at bottom. hope this helps, and if there are better ways out there, I would love to here them. 1305.6 [Heating Oil Storage Tank] Fill piping. Fill piping shall comply with the requirements of Sections 1305.6.1 through 1305.6.6. 1305.6.1 Size. Fill piping shall be a minimum of 2 inches (51 mm)in diameter or 3 inches (76 mm)for No. 6 fuel oil. 1305.6.2 Termination location. 13. Wire the tank or system/pipe sensor connected to the DHW sensor terminals on the follower boiler addressed as #1. 14. The system/pipe sensor must be placed on common piping to the tank, as close to the tank as possible. 15. The system/pipe sensor is wired to the system sensor terminals on the master boiler. Each air pipe from a double bottom tank, deep tanks which extend to the ship’s side, or any tank which may be run up from the sea, is led up above the bulkhead deck. From oil fuel and cargo oil tanks, cofferdams, and all tanks which can be pumped up, the air pipes are led to an open deck, in a position where no danger will result from leaking ...

An Aboveground Storage Tank (AST) Facility or tank farm consists of tanks (including day tanks), piping, secondary containment and ancillary equip-ment. These facilities are used to store fuel that will be dispensed at the site, ... • Valves control the flow of oil between tanks and other tanks, delivery barges and other sources. The most ... NO. 2 OIL TEMPERATURE CONTROL. SYSTEM (TYPICAL-PROVIDE A COMPLETE. SYSTEM FOR EACH ABOVEGROUND. TANK). XHEV. H-. ELECTRIC OIL HEATER H. BPV. FUEL OIL BACK.1 page Sealing your Primary Oiler · Oil System Diagram · Very Simplified Oil line Routing · Oil Line Routing · Amsoil Oil Comparison Study · Factory option oil. Shovelhead - Oil line routing on 76 FLH w/stock tank. - Restoring a 76 FLH. Need oil line routing diagram for stock oil tank. My sifton oil pump.Jan 07, · This video was uploaded from an ...

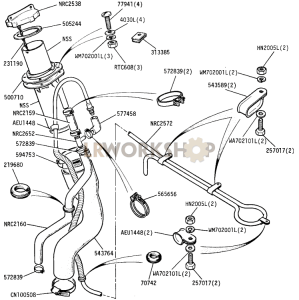

Brake Piping Brake Oil Tank And Rerated Parts Wheel Loader Komatsu Wa1200 3 Operator S Compartment And Control System 777parts

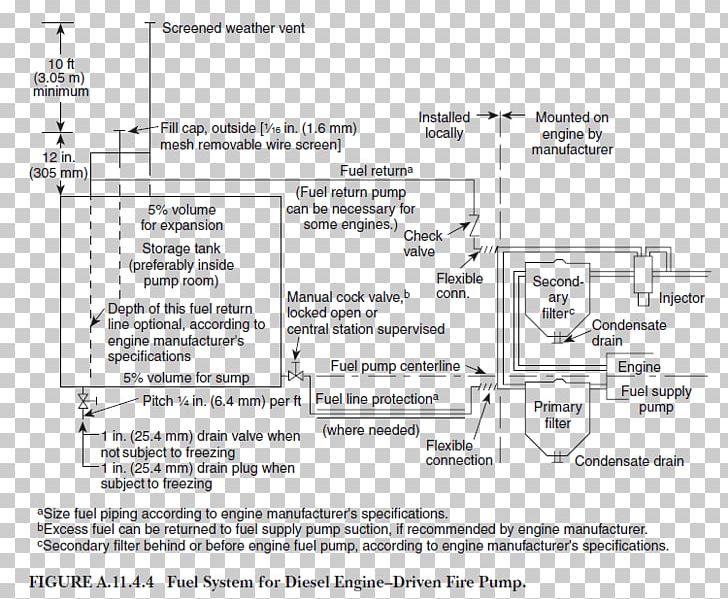

Fire Pump National Fire Protection Association Diesel Fuel Storage Tank Piping Png Clipart Angle Area Black

Brake Oil Piping Brake Oil Tank To Brake Chamber Tbg Spec 10001 10391 Wheel Loader Komatsu Wa500 1 A Drive Shaft Differential And Wheels 777parts

0 Response to "37 oil tank piping diagram"

Post a Comment